Specification of the Laser Pipe Cutting Machine

| Item | Specification |

|---|---|

| Performance Specification | |

| Max Tube/Profile Cutting Length | The Laser pipe Cutting Machine can handle up to 6000mm. |

| Cutting Capacity of Square Tube | □20*20-□150*150mm |

| Cutting Capacity of Round Tube | Φ20-Φ220mm |

| X/Y-axis Positioning Accuracy | ±0.03/1000mm |

| Repeated Positoning Accuracy | ±0.02/1000mm |

| Max Accelerated Speed | 1.0 G |

| Max Linear Moving Speed | 100 m /min |

| Max Chuck Rotary Speed | 100 rpm/min |

| Tailing | ≥ 0mm |

| Mechanical Specification | The Laser pipe Cutting Machine offers advanced mechanical features. |

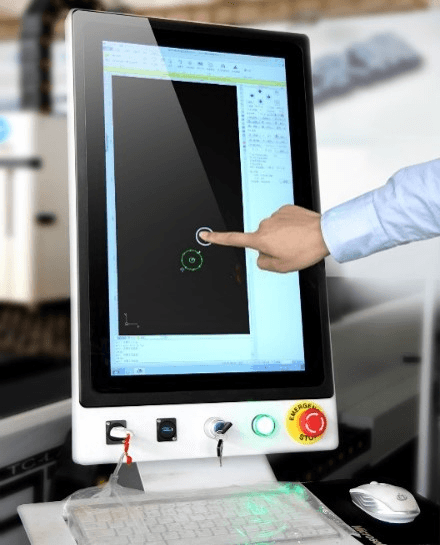

| Control System | Cypcut Fscut3000S |

| HMI Pattern | Super Touch Screen |

| Cutting Software | FSCUT TubePro 3D Cutting Software |

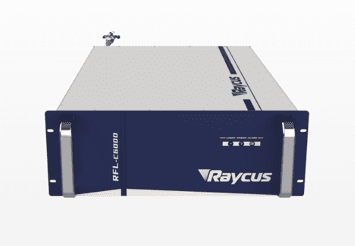

| Laser Source | Raycus3000w |

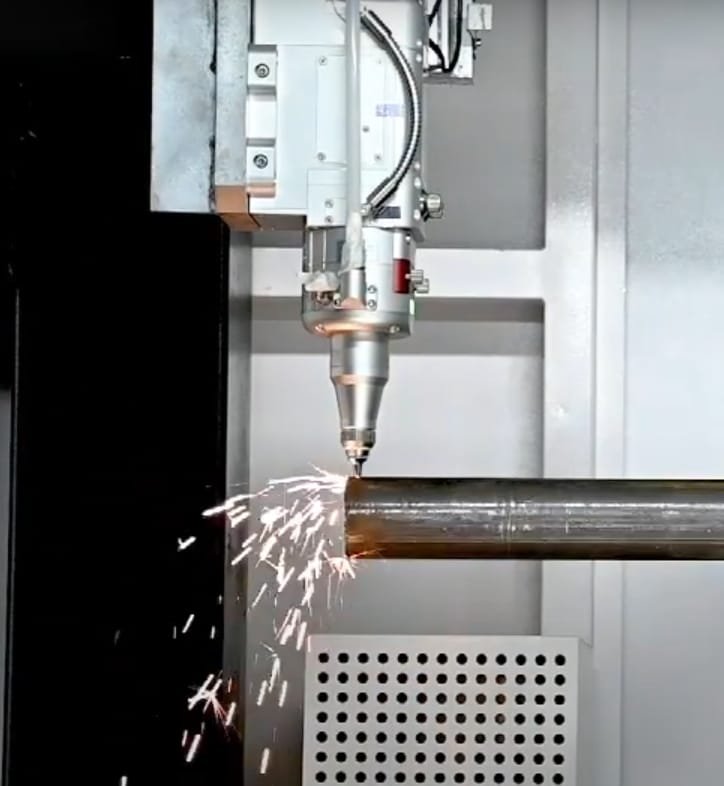

| Laser Cutting Head | Raytool Auto Focus Cutting Head |

| Cooling System | Hanli Water Chiller |

| Servos and Motor | Yaskawa Servo Motor system |

| Reducer | Nidec ( shimpoo Reducer from Japan ) |

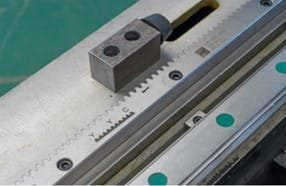

| Transmission System | YYC Rack and Pin, HIWIN Guide Rails |

| Bed Body | Plate-welded,Excellent engineered ,Stress-Relieved |

| Pipe Support System | Servo Floating Follow-up support & Platform servo support |

| Pipe Chuck Pattern | Automatic Triple Pneumatic 220 Chucks |

| No.of Pipe Chuck | The Laser pipe Cutting Machine features 3x220mm pipe chucks. |

| Electronic Parts | Schneide /Omron and Igus Cable |

| Hydraulic Parts | SMC/ AirTec Brand |

| Electric Control Cabinet | Independent |

| Smoke Dust Removal System | Eifficient exhaust System with 3KW Air Fan |

| Lubricated System | Automatic |

| Bevel Cutting | Optional |

| Power Supply | 380V, 50HZ±10% |

| Auxiliary Gas | Compressed air, Oxygen, Nitrogen |

| Loading System | 6mm Semi Automatic Loading Device (can be tailed ) |

| Unloading System | 6m Semi Automatic Unloading Device (can be tailed ) |

| Valves | O2 Proportional Valve & N2 Proportional Valve |

| AC System | An Air Conditioner for Electric Cabinet |

The Main Parts of the Pipe Laser cutting Machine

01.

02.

03.

04.

05.

Yaskawa Servo Motor

HIWIN Guide Way

Shimpoo Reducer

High Accurate Rack and Pin

06.

07.

04.

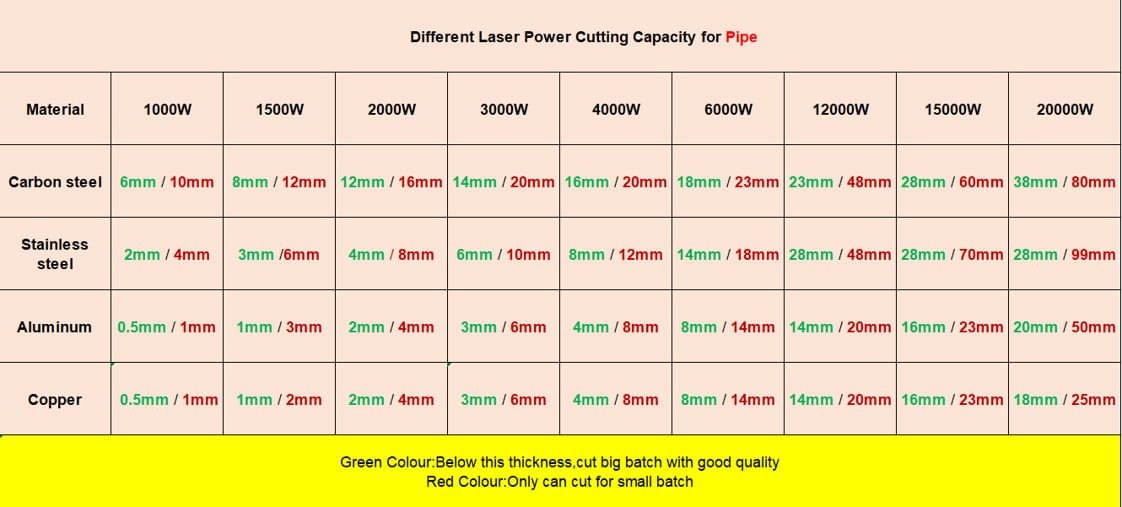

The Cutting Capacity of the tube laser cutting machine

The Delivery of the laser pipe cutting machine