Octg Pipe finishing Machine &production line expert

Pipe finishing machine for OCTG pipe delivers precision and reliability. Pipe finishing machine for OCTG pipe enhances surface quality and dimensional accuracy. Moreover, OCTG pipe finishing machine integrates advanced straightening, cutting, and end-facing. In addition, threading and non-destructive testing ensure every pipe meets strict standards. Furthermore, pipe finishing line for OCTG pipe includes hydrostatic testing, marking, and anti-corrosion treatment. As a result, finished pipes are ready for packaging and storage. Our solutions offer flexible configurations for different pipe types. Besides, we provide one-stop service from design to installation and automation. Consequently, clients benefit from efficient production and superior quality. Choose our OCTG pipe finishing machine for consistent results and industry-leading expertise.

A Legacy of Innovation and Inspiration

Pipe finishing machine for OCTG pipe is our core expertise. Pipe finishing machine for OCTG pipe enables complete solutions for global clients. As a leading manufacturer in China, we deliver OCTG pipe finishing machine and pipe finishing line for OCTG pipe and coupling production. With over 20 years of experience, our team engineers every pipe finishing line for OCTG pipe from concept to full automation. Moreover, our advanced technology ensures high efficiency and premium quality.

You can rely on us for integrated lines or stand-alone machines tailored to your needs. In addition, we offer quality control equipment with unique performance features. Our finishing lines include OCTG finishing lines, boiler tube finishing lines, and heat treatment lines. We manufacture comprehensive pipe end finishing machines for OCTG pipe and line pipe production. Our range covers cutting, threading, facing, chamfering, and sizing.

Furthermore, we provide measuring, hydro-testing, coating, and marking machines. Our OCTG pipe finishing machine uses advanced finishing technology and intelligent automation to meet API standards. Choose our pipe finishing line for OCTG pipe and experience industry-leading innovation and dedicated service.

What we Expert and service Offer

octg Pipe Threading Line and Equipment introduction

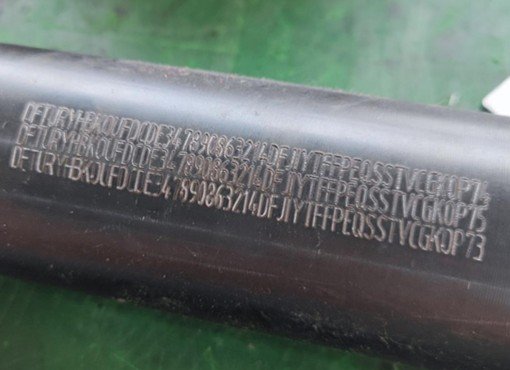

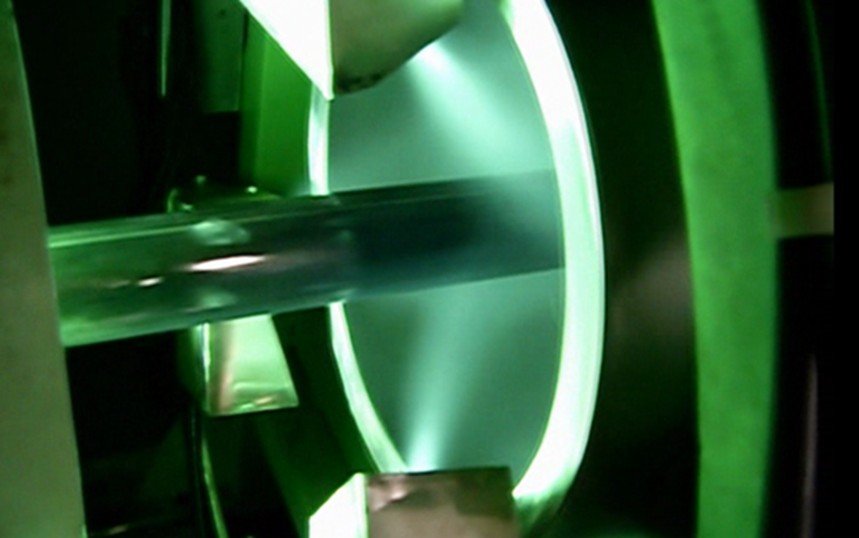

Our Pipe Finishing Machine for OCTG Pipe delivers precision and efficiency for oil and gas applications. This advanced Pipe Finishing Machine for OCTG Pipe integrates CNC threading, pipe end sizing, magnetic particle inspection, and sandblasting. Robotic loading ensures smooth transitions, while automated oil coating and protector assembly maintain product integrity. Length measurement, weighing, marking, and painting complete the process with accuracy.

The OCTG pipe finishing machine supports API and premium threads across a wide diameter range from 2-1/2” to 20”. Its modular design offers flexibility and reliability for demanding environments. Smart automation reduces manual labor and improves consistency. Full traceability guarantees quality control at every stage.

Our pipe finishing line for OCTG pipe combines robotics and intelligent systems for seamless operation. It minimizes downtime and maximizes throughput. Energy sector manufacturers benefit from high precision and reduced costs. Advanced integration enhances safety and ensures uniform performance.

Choose this OCTG pipe finishing machine to achieve superior results. It transforms traditional workflows into smart manufacturing solutions. With automated processes and real time monitoring, your production line becomes faster, safer, and more efficient. This technology empowers your business to stay competitive and meet global standards.

the main Composition of the pipe threading Line

Pipe Swaging Machine

Pipe Theading Machine

Magnetic Particle Inspector

sand Blasting Machine

Robotic coupling Starter system

Coupling Make-up Machine

Hydrostatic Test System

Long Drifter Equipment

Robotic Protector Applicator

Length Measurement Device

Stamping Marking System

Coating and Painting System

Coupling Threading Line and Equipment introduction

In OCTG production, the coupling threading line automates thread cutting for couplings. The main equipment is a CNC coupling threading machine. It offers high rigidity, precision, and reliability. After cutting and OD turning, robots send each coupling blank to the threading unit. The machine uses a swivel chuck design. Thus, it finishes threads on both ends in one step, improving efficiency and thread quality.

During processing, the CNC system, such as Siemens 840D, controls tool movement precisely. This ensures thread size and shape accuracy. After threading, the system inspects threads automatically. Robots transfer qualified couplings to further inspection and surface treatment. Unqualified pieces are sorted out automatically. The line includes hydraulic, lubrication, and cooling systems. These systems keep equipment stable and maintain product quality.

The coupling threading line meets API and Premium thread standards. It supports various coupling sizes. By connecting to the MES system, the line achieves smart management and quality tracking. As a result, production efficiency and consistency increase significantly.

the main Composition of the pipe threading Line

Rotary Tool Cutting Machine

Coupling Theading Machine

Magnetic Particle Inspector

sand Blasting Machine

Coupling Phosphating Complete

Coupling Drying Unit

The Main Equipment we Supplied

We manufacture full-length finishing machines for OCTG and line pipes. These machines include cutting, threading, end facing, chamfering, and sizing equipment. They deliver precise tolerances that meet API and GOST standards. As a result, production remains stable and efficient even in harsh environments. Moreover, advanced designs ensure smooth operation and reduce downtime. Our machines improve workflow, enhance accuracy, and boost productivity. Therefore, customers achieve consistent quality and lower costs. With robust construction and reliable performance, they withstand extreme conditions without compromise. In addition, intuitive controls simplify operation and maintenance. Consequently, users experience faster setup and higher output. We focus on innovation and durability to support demanding applications worldwide

The Main Intelligent Solution we supplied

We deliver intelligent automation solutions for steel pipe finishing lines. Our systems include smart coupling loading and unloading, the Coupling Starter System ,pre-tightening system and the Robotic Protector Application System. In addition, advanced marking and color band spraying ensure consistent quality with minimal human input. Moreover, we provide cutting-edge automation for the metallurgical industry, including Steel Coil De-bander robots and hot billet marking systems. These intelligent solutions reduce repetitive and hazardous tasks while boosting efficiency. Therefore, customers achieve faster production

Discover Our Full Range