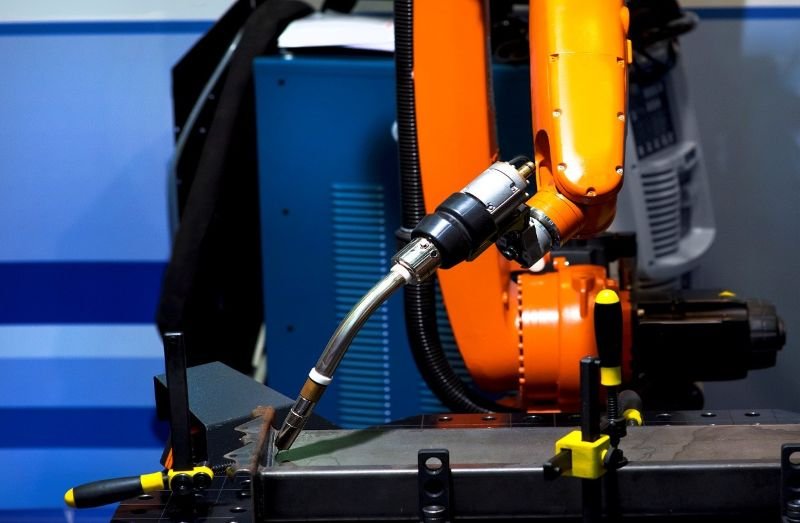

Robotic Welding automation Solution

Robotic welding automation solution delivers advanced welding automation for modern manufacturing. Welding automation improves efficiency and precision in every process. Our robotic welding automation solution integrates robots, welding machines, positioners, and fixtures for seamless operation. It ensures fast setup and smooth workflow while reducing costs. Because of its modular design, you can easily customize configurations to meet specific needs.

Moreover, the system offers strong compatibility and flexible options for diverse applications. As a result, businesses achieve higher productivity and consistent weld quality. In addition, intuitive controls and quick commissioning simplify daily operations. Therefore, companies can accelerate production and maintain efficiency without compromise.

Furthermore, the solution supports multiple welding processes, making it ideal for complex projects. Its robust structure guarantees durability and long-term reliability. With advanced sensors and smart control software, precision and safety are always maintained. Consequently, manufacturers can reduce downtime and improve overall output.

Welding automation also minimizes material waste, which helps lower operational expenses. Because of these benefits, it is a perfect solution for industries seeking automation and cost efficiency. Choose our robotic welding automation solution to experience reliable welding automation that saves time, boosts performance, and drives growth.

Invest today and transform your welding process into a smarter, faster, and more profitable operation. Our team is ready to deliver tailored solutions that meet your unique requirements. Partner with us and embrace the future of welding automation with confidence and efficiency.

robotic Welding System Live Show