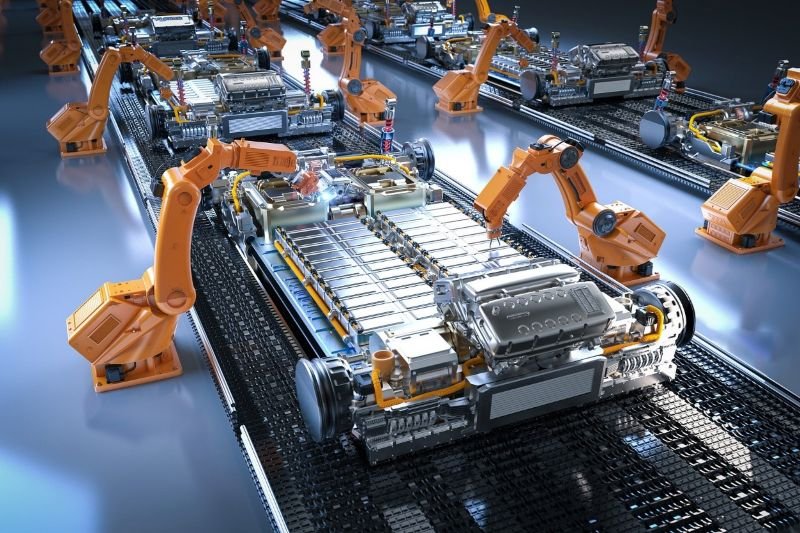

Robotic Automation For Battery Production

Automation for battery production is revolutionizing modern manufacturing. Automation for battery production improves efficiency and ensures consistent quality. Robotic automation for battery production combines advanced robotics with intelligent control systems to streamline every stage of the process. The battery automation line includes a six-axis robotic arm, precision tooling, and a visual location system. These components work together to guarantee accuracy and reliability. A well-programmed control system drives smooth operations and reduces downtime.

The automated battery production line offers significant advantages. It enables automated feeding, assembly, loading, and unloading, which minimizes human error and accelerates workflow.

Intelligent management allows real-time monitoring and quick adjustments, ensuring high-quality output. Moreover, the digitalization of the entire battery automation line enhances productivity and reduces operational costs. Manufacturers benefit from faster turnaround and improved flexibility, meeting market demands efficiently.

Robotic automation for battery production also supports global scalability. Our solutions have been designed and implemented worldwide, earning recognition for performance and reliability. By adopting this advanced technology, companies achieve superior control, reduce labor dependency, and increase overall output. The integration of automation for battery production demonstrates how innovation can transform traditional processes into smart, efficient systems.

In summary, the battery automation line represents a future-ready approach to manufacturing. It combines speed, precision, and intelligent control to deliver exceptional results. Embracing robotic automation for battery production ensures competitiveness and long-term success in a rapidly evolving industry.

robotic Automation For Battery Production live Show

Discover Our Full Range