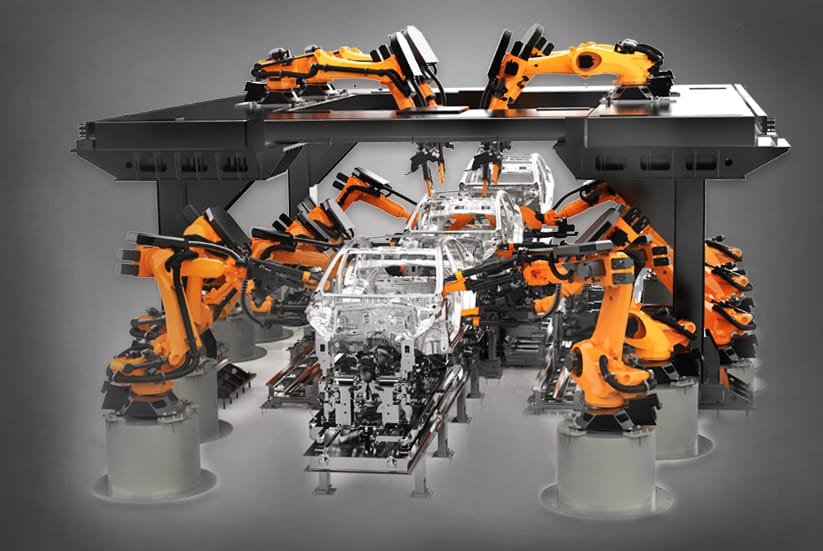

Robotic Automation For BIW Welding Industry

Robotic Automation for BIW Welding is transforming automotive manufacturing. Robotic Automation for BIW Welding improves efficiency and ensures precision in Body-In-White assembly. Our advanced BIW welding automation systems deliver turnkey solutions for high-volume and low-volume production. Each line is tailored to meet specific customer needs, offering flexibility and reliability. Automated production lines can achieve outputs from hundreds to over 2,000 cars daily. For smaller projects, we provide manual and semi-automatic options, ensuring every client finds the right solution.

Biw welding automation integrates advanced joining technologies such as folding, clinching, gluing, MIG welding, and laser welding. Vision systems enhance accuracy by guiding part positioning and handling. These features reduce errors and improve consistency. Intelligent control systems streamline operations and allow real-time adjustments, boosting productivity. Additionally, automation in transportation and joining processes minimizes downtime and optimizes workflow.

Digital engineering enables seamless integration of new models into existing facilities. This approach accelerates changeovers and supports continuous improvement. By adopting BIW welding automation, manufacturers gain superior quality control and faster turnaround times. The combination of robotic precision and smart management ensures competitive performance in a demanding market.

In summary, robotic automation for BIW welding sets new standards for automotive production. It combines speed, accuracy, and flexibility to deliver exceptional results. Embracing this technology positions manufacturers for long-term success and operational excellence.

bIW Robotic Welding Automation Live Show

The Excellent BIW Production Solution We Offer

We deliver advanced BIW production solutions using Robotic Automation for BIW Welding. Our closures system automates hemming, welding, handling, and sealing for maximum efficiency. For body side production, we enable random assembly of multiple models with turntable and fixture library changeover, ensuring seamless welding and sealing through robots and APC. Our framing solution offers high-speed transfer via roller beds and flex pallets, supporting multi-model random production with precision framing technology. These integrated systems reduce downtime, improve flexibility, and boost productivity. By adopting robotic automation for BIW welding, manufacturers achieve superior quality and operational excellence in automotive body assembly.

Closures Automatic Production Solution

Automatic production is achieved through an integrated sequence of advanced processes, including robotic hemming, precision welding, arc‑welding operations, automated handling, and high‑performance sealing. By combining these technologies into a unified workflow, the system ensures consistent quality, improved production efficiency, and stable, repeatable output across all closure‑related manufacturing tasks. This solution supports scalable automation and enhances overall manufacturing reliability.

Body Side Automatic Production Solution

This solution enables flexible, mixed‑model production through a turntable system and rapid fixture‑library changeover. By integrating robotic welding, automated sealing, intelligent handling, and APC‑based process control, the line achieves full automation across all key operations. The system supports random model assembly, enhances production stability, and delivers consistent quality while maximizing efficiency in body‑side manufacturing.

Body Side Automatic Production Solution

This solution enables flexible, mixed‑model production through a turntable system and rapid fixture‑library changeover. By integrating robotic welding, automated sealing, intelligent handling, and APC‑based process control, the line achieves full automation across all key operations. The system supports random model assembly, enhances production stability, and delivers consistent quality while maximizing efficiency in body‑side manufacturing.

Framing Automatic Production Solution

This solution enables high‑speed, high‑precision BIW transfer through an integrated high‑speed roller bed and flexible pallet system. Leveraging advanced framing technology, the line supports true multi‑model random production with rapid changeover and stable positioning accuracy. The system ensures consistent dimensional quality, improved takt performance, and fully automated coordination across all framing operations.

Discover Our Full Range