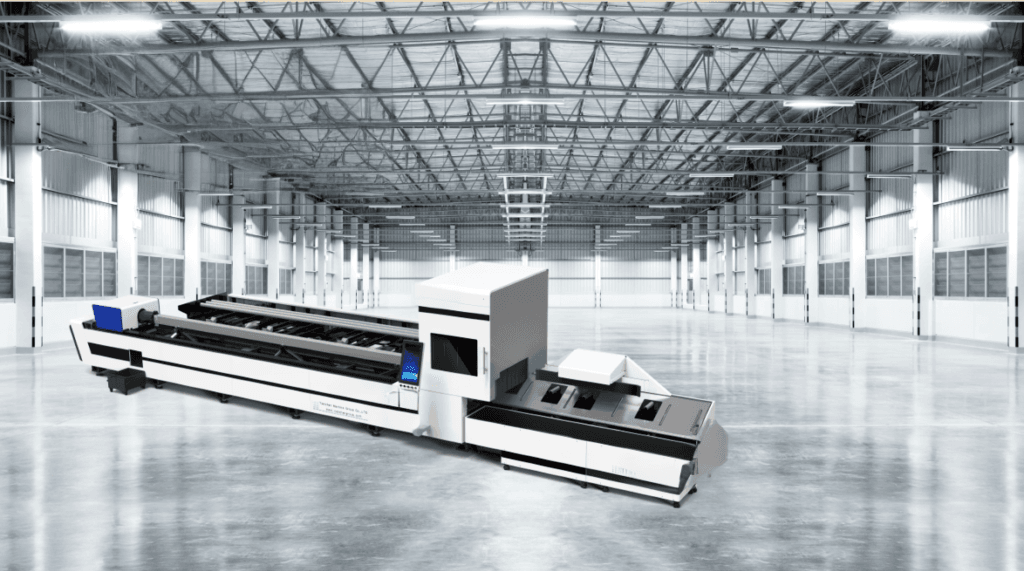

Tube Laser Cutting Machine -HTTC-320A

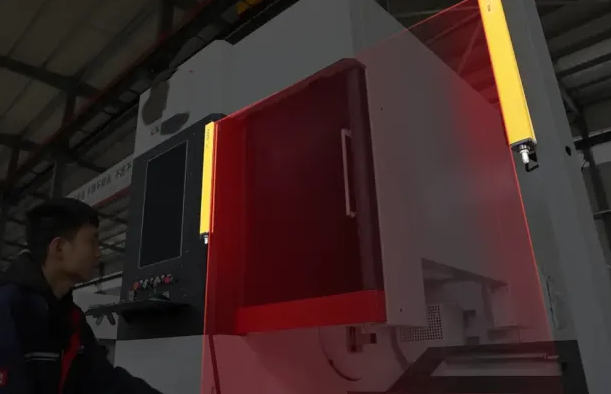

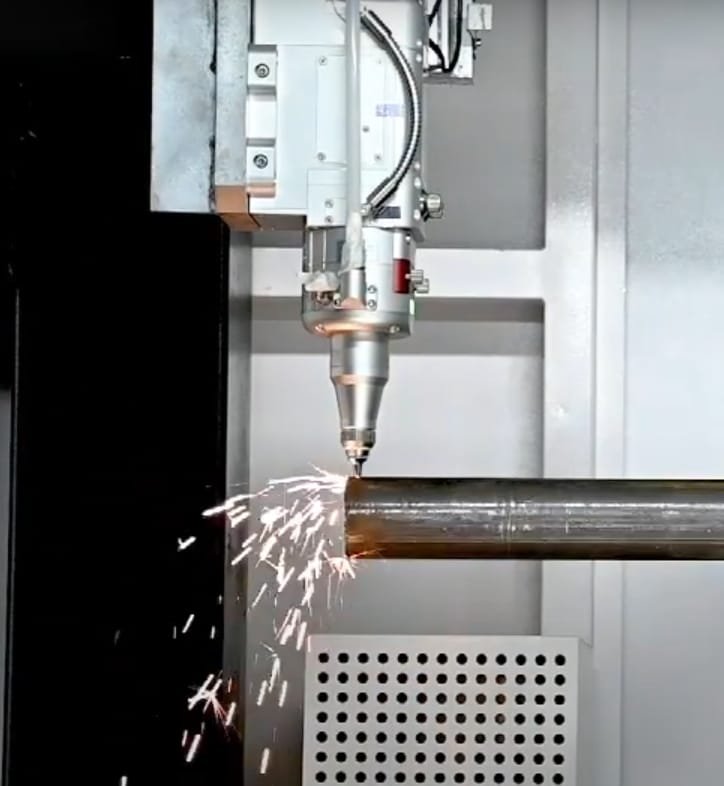

The HT-T320A Tube laser cutting machine delivers precision and speed for tube and pipe fabrication. This advanced tube laser cutting machine uses fiber laser technology to ensure efficient and accurate cutting. With its innovative bus control system, the laser pipe cutting machine operates smoothly, improving productivity for manufacturers.

Its rack transmission system combined with a follow-up roller enhances cutting accuracy, making complex designs simple. The pipe laser cutting machine can process square pipes, round pipes, oval pipes, waist-round pipes, and special-shaped pipes. This versatility allows industries to achieve customized solutions with ease.

From sports equipment manufacturing to oil pipeline fabrication, the laser cutting machine tube guarantees consistent results. It supports water supply systems and other applications, making it an essential tool for modern production. Choose the HT-T320A Tube laser cutting machine for precision, speed, and flexibility in every project.

key Advantage Of the Laser Cutting Machine

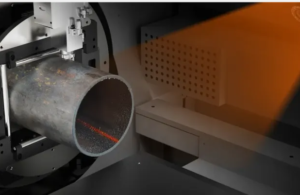

01/Cutting Ability

HTTC-320ASeries high efficient laser Tube cutting machine, can cut any metal Tubes, with the length of 6-12m, the diameter 8-350mm, and the weight of 1.5 tons or less;

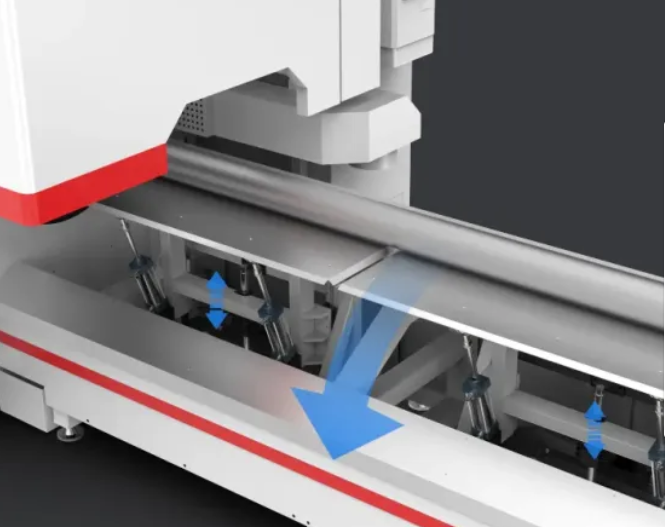

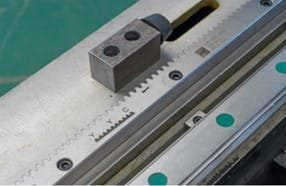

02/Chuck technology

square hole design, strong Tube passing rate, achieving the widest working range, helping reduce equipment investment;

03/User-friendly design

weld identification, safety light curtain, dust removal design, etc. well protect workers, machines and work-pieces

04/High dynamic performance

machine with 120mm chucks, chuck moving speed 110m/min, speed 200r/min, acceleration 1.5G;

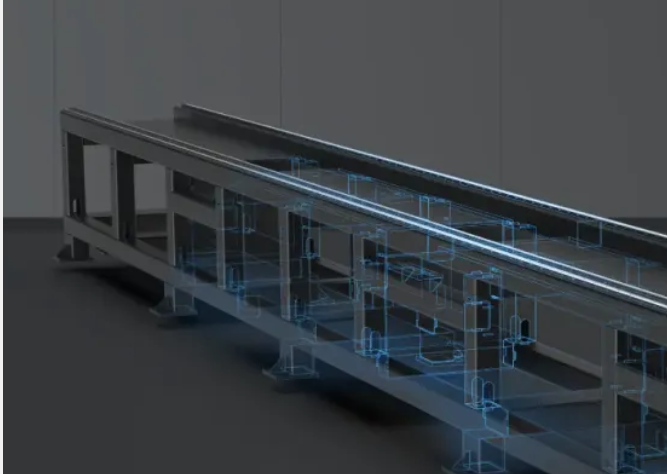

05/More self-developed technologies

mortise and tenon structure bed, segmented servo support, automatic unloading device, etc., to ensure cutting accuracy;

The Unique Innovative technology

The Unique User-friendly design

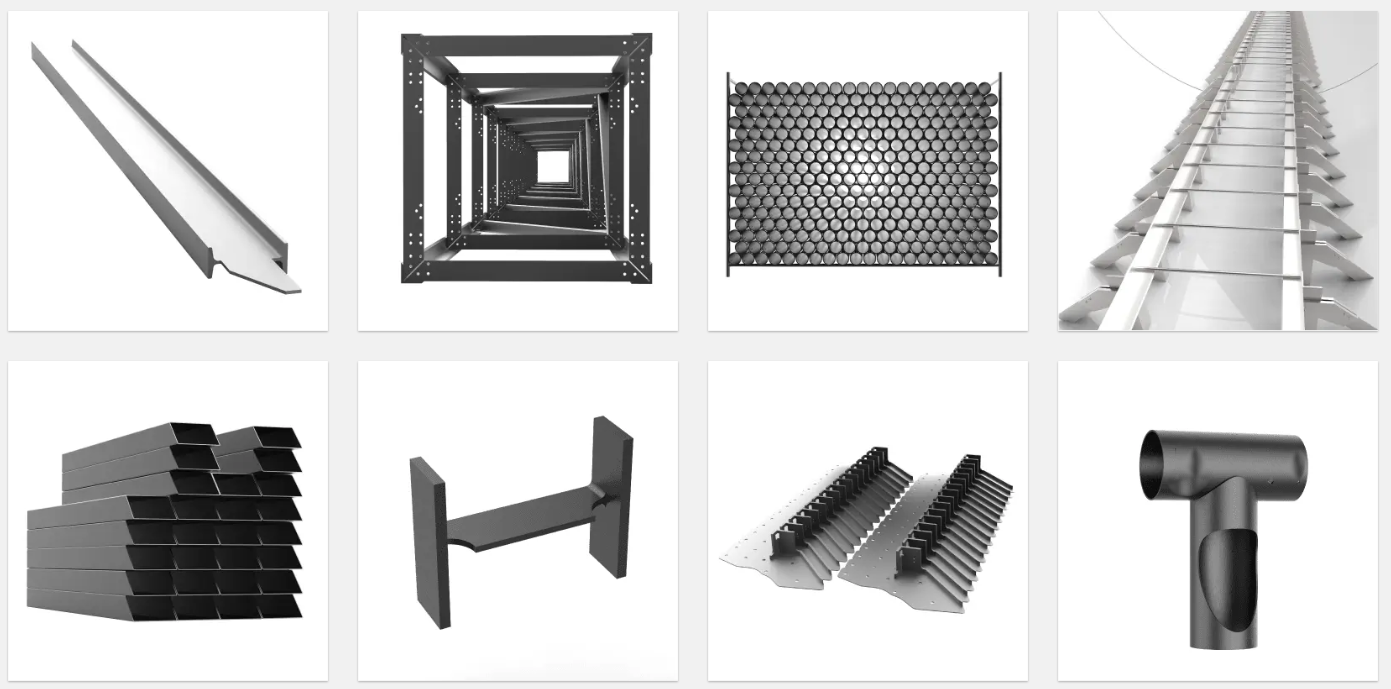

Laser Tube Cutting Show Case

Specification of the Machine

| Item | Specification |

|---|---|

| Performance Specification | The Advantage performance of the tube laser cutting machine ensure your prodution |

| Max Tube/Profile Cutting Length | 6000mm |

| Cutting Capacity of Square Tube | □20*20-□200*200mm |

| Cutting Capacity of Round Tube | Φ8-Φ350mm |

| X/Y-axis Positioning Accuracy | ±0.03/1000mm |

| Repeated Positoning Accuracy | ±0.02/1000mm |

| Max Accelerated Speed | 1.5 G |

| Max Linear Moving Speed | 120 m /min |

| Max Chuck Rotary Speed | 200 rpm/min |

| Tailing | ≥ 0mm |

| Mechanical Specification | |

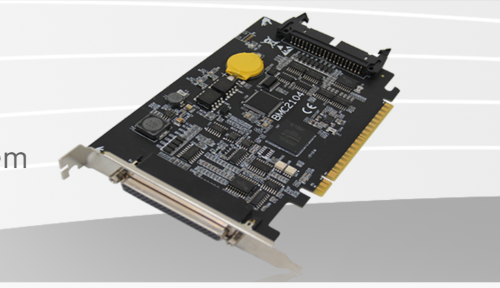

| Control System | Cypcut Fscut3000S |

| HMI Pattern | Super Touch Screen |

| Cutting Software | FSCUT TubePro 3D Cutting Software |

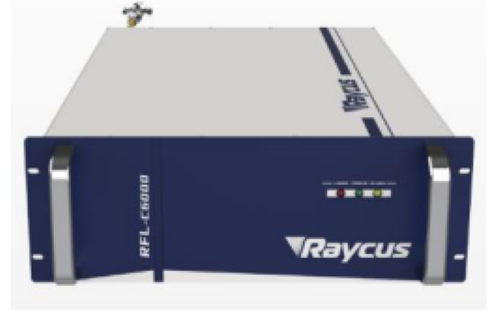

| Laser Source | Raycus3000w |

| Laser Cutting Head | Raytool Auto Focus Cutting Head |

| Cooling System | Hanli Water Chiller |

| Servos and Motor | Yaskawa Servo Motor system |

| Reducer | Nidec ( shimpoo Reducer from Japan ) |

| Transmission System | YYC Rack and Pin, HIWIN Guide Rails |

| Bed Body | Plate-welded,Excellent engineered ,Stress-Relieved |

| Pipe Support System | Servo Floating Follow-up support & Platform servo support |

| Pipe Chuck Pattern | Automatic Triple Pneumatic 320 Chucks |

| No.of Pipe Chuck | 2x320mm |

| Electronic Parts | Schneide /Omron and Igus Cable |

| Hydraulic Parts | SMC/ AirTec Brand |

| Electric Control Cabinet | Independent |

| Smoke Dust Removal System | Eifficient exhaust System with 3KW Air Fan |

| Lubricated System | Automatic |

| Bevel Cutting | Optional |

| Power Supply | 380V, 50HZ±10% |

| Auxiliary Gas | Compressed air, Oxygen, Nitrogen |

| Loading System | 6mm Semi Automatic Loading Device (can be tailed ) |

| Unloading System | 6m Semi Automatic Unloading Device (can be tailed ) |

| Valves | O2 Proportional Valve & N2 Proportional Valve |

| AC System | An Air Conditioner for Electric Cabinet |

Advanced configuration

cutting Sample Showcase

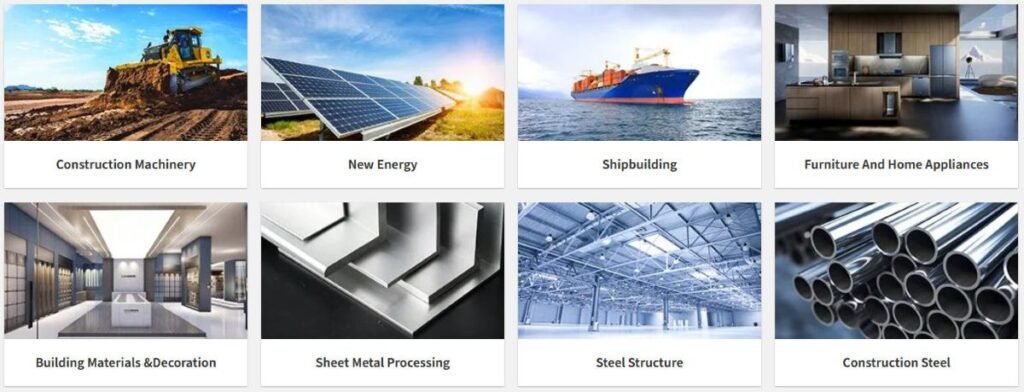

Industrial Laser Cutting Application

Discover Our Full Range