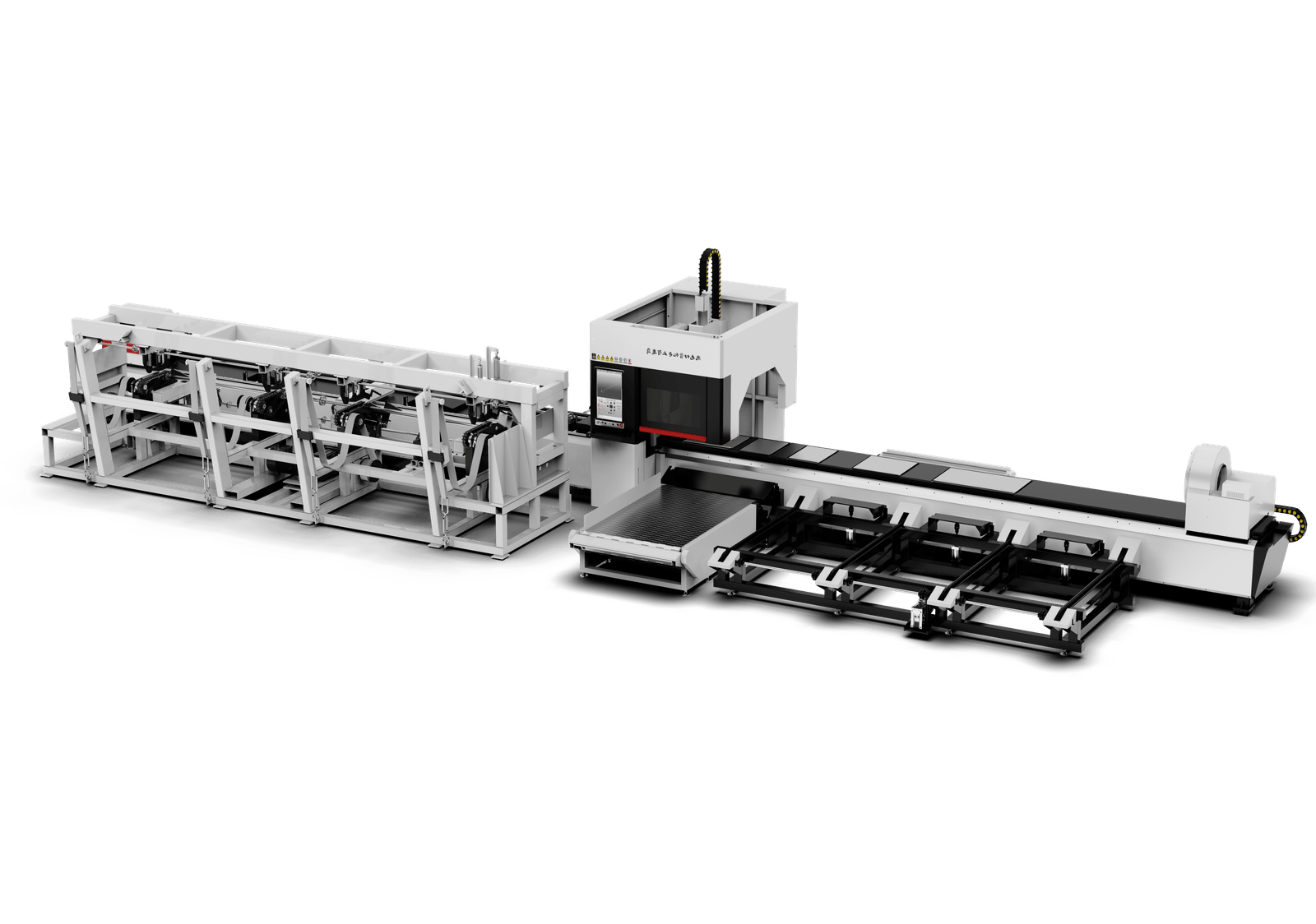

Laser Tube Cutting Machine -HTLT-12035GA

The HTLT-12035GA laser tube cutting machine delivers precision and power for heavy-duty tasks. This advanced laser tube cutting machine belongs to the HTG laser cutting machine tube series, designed to process metal tubes from 16mm to 350mm in diameter. As part of the laser cutting machine tube lineup, it ensures reliable performance for diverse applications.

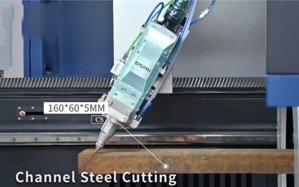

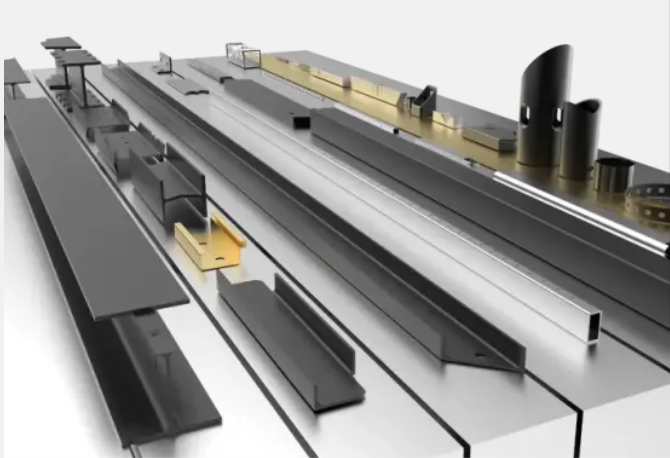

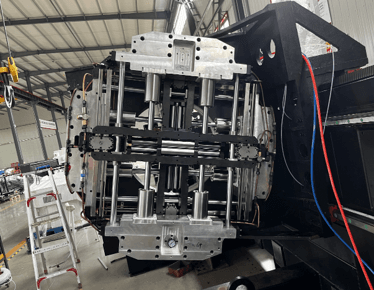

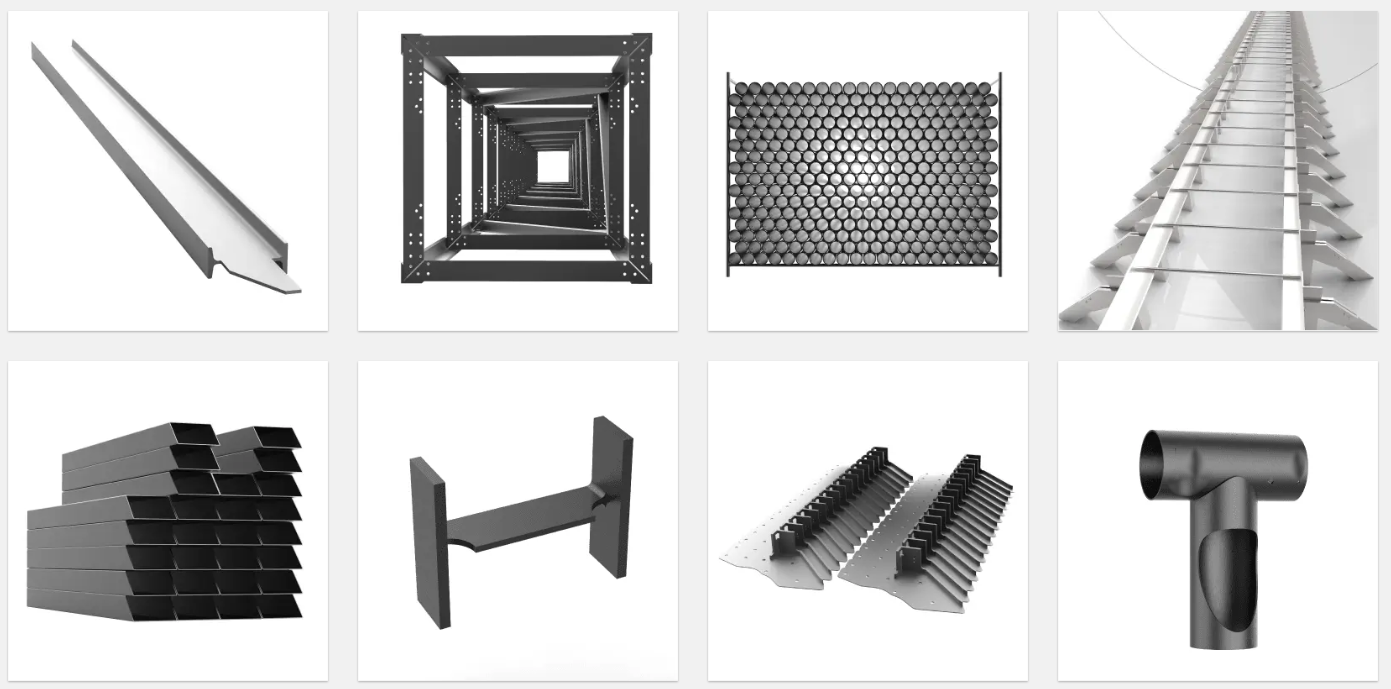

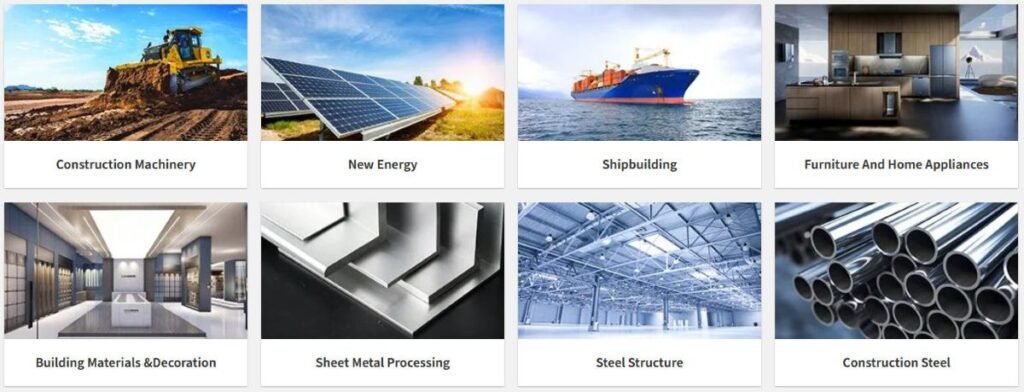

It cuts various tube shapes, including round, square, rectangular, oval, and channel steel. Moreover, the machine supports H steel and angle iron, making it ideal for industries such as new energy, construction steel, automobile manufacturing, and heavy machinery. The laser pipe cutting machine uses a triple-chuck system with full-stroke pneumatic chucks and servo followers, ensuring stability and efficiency.

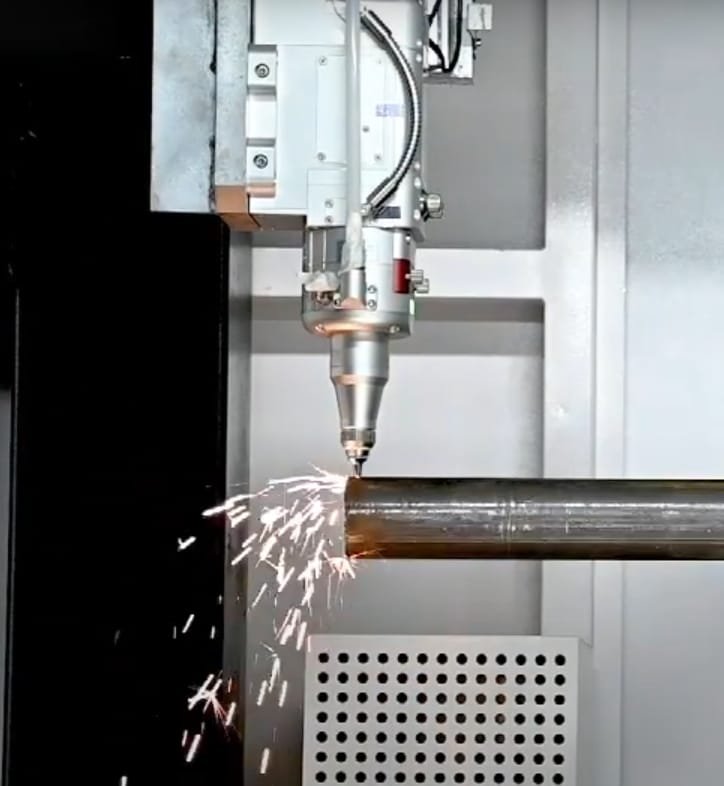

Additionally, the Ospri autofocus cutting head guarantees accurate results. It maintains consistent cutting height and adjusts the focus automatically for different drilling and cutting needs. The three-chuck zero tailing technology reduces material waste, enabling ultra-long tube cutting without leftover tails. As a result, this pipe laser cutting machine improves productivity and lowers costs while delivering superior performance for complex applications.

key Advantage

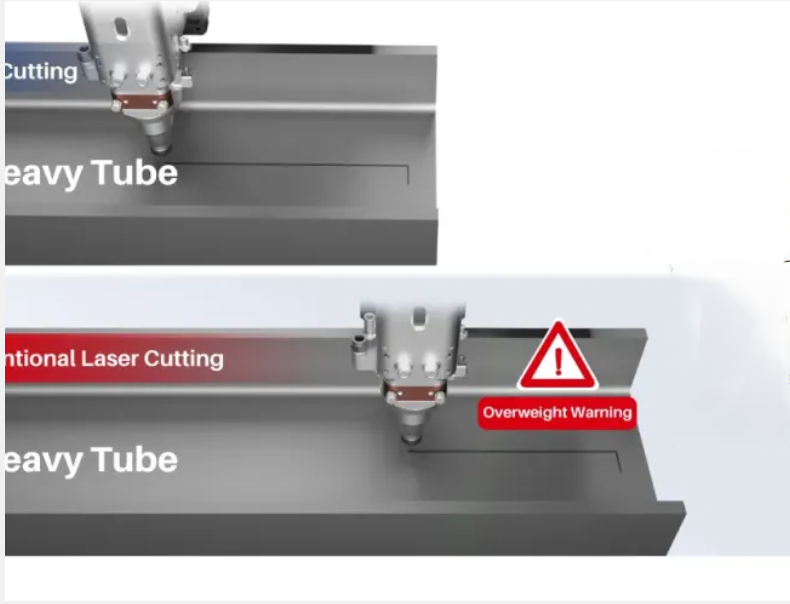

01/Cutting Ability

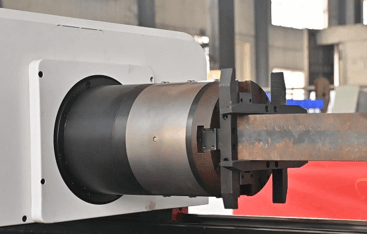

G series zero tailing laser Tube cutting, can cut any metal Tubes, with the length of 6-12m, the diameter 8-350mm, and the weight of 1.5 tons or less;

02/Full-stroke chucks

No need to change the chuck claws to improve productivity; the clamping force is twice as strong as ordinary ones

03/Zero tailing cutting

saves production costs and meets more complex cutting needs;

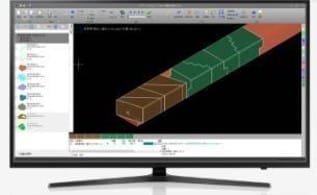

04/3D bevel cutting

Support V-bevel Y-bevel X-bevel K-bevel and gradient cutting. Cutting section is good, no burr, no need secondary process, upgrading the qualified rate of finished products

05/High dynamic performance

High-performance bus servo motor, the maximum feeding speed up to 100m/min, ensuring the running speed of machine

The laser Tube cutting machine Showcase

Specification of the Laser Tube Cutting Machine

| Item | Specification |

|---|---|

| Performance Specification | |

| Max Tube/Profile Cutting Length | 12300mm |

| Cutting Capacity of Round Tube | Φ20-Φ350mm |

| X/Y-axis Positioning Accuracy | ±0.05/1000mm |

| Repeated Positoning Accuracy | ±0.03/1000mm |

| Max Accelerated Speed | 1.0 G |

| Max Chuck Rotary Speed | 85 rpm/min |

| Tailing | ≥ 0mm |

| X-Axis Travel | 800mm |

| X-Axis Max Moving Speed | 120m/min |

| Y-Axis Travel | 13400 mm |

| Y-Axis Max Moving Speed | 120m/min |

| Z-Axis Travel | 400 mm |

| Z-Axis Max Moving Speed | 80 m/min |

| Mechanical Specification | |

| Control System | FSCUT 5000A Ethercat control system |

| HMI Pattern | Super Touch Screen |

| Cutting Software | FSCUT TubePro 3D Cutting Software |

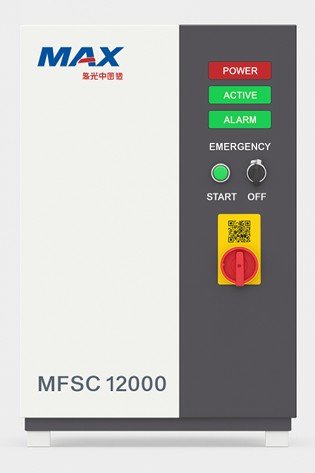

| Laser Source | MAX Laser Source- 12000W |

| Laser Cutting Head | OSPRI or BOCI Laser Head |

| Cooling System | Hanli Water Chiller |

| Servos and Motor | China Inovance Ethercat Servo Motors |

| Reducer | Nidec ( shimpoo Reducer from Japan ) |

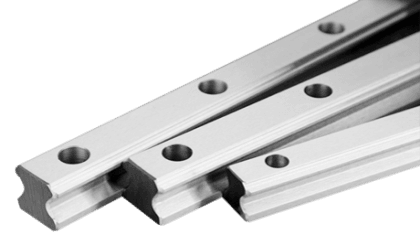

| Transmission System | YYC Rack and Pin, HIWIN Guide Rails |

| Bed Body | Stress- Reliefed , Time-Aged , Excellent machined and Great -Engineered Bed |

| Pipe Support System | Servo Floating Follow-up support & Platform servo support |

| Pipe Chuck Pattern | Automatic Triple Pneumatic 350 Chucks |

| No.of Pipe Chuck | 3x350mm |

| Electronic Parts | Schneide /Omron and Igus Cable |

| Hydraulic Parts | SMC/ AirTec Brand |

| Electric Control Cabinet | Independent |

| Smoke Dust Removal System | Eifficient exhaust System with 3KW Air Fan |

| Lubricated System | Automatic |

| Bevel Cutting | Optional |

| Power Supply | 380V, 50HZ±10% |

| Auxiliary Gas | Compressed air, Oxygen, Nitrogen |

| Loading System | 12mm Semi Automatic Loading Device (can be tailed ) |

| Unloading System | 12m Semi Automatic Unloading Device (can be tailed ) |

| Valves | O2 Proportional Valve & N2 Proportional Valve |

| AC System | An Air Conditioner for Electric Cabinet |

The Unique User-Friendly Design

The Unique Innovative technology

The Main Parts of the machine

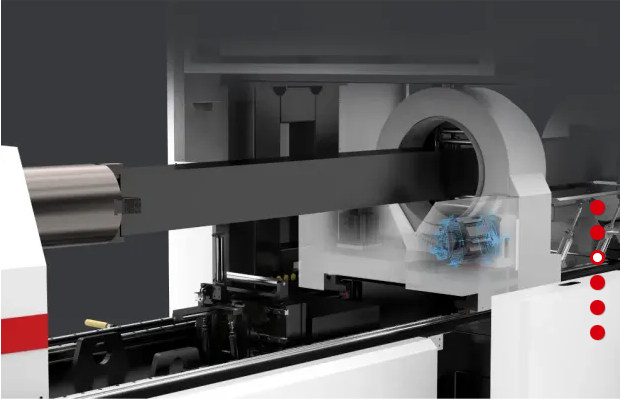

01 / Raytool cutting head

The cutting head accelerates faster through a lightweight design, ensuring smooth and precise performance.

Moreover, we replace traditional air cooling with high-speed airflow and lens optical shaping for better results.

In addition, the first domestic water-cooled nozzle structure improves stability and surface quality during steel cutting.

Consequently, efficiency increases significantly, reducing downtime and enhancing overall productivity for demanding tasks.

For advanced needs, you can choose the Ospri bevel cutting head with ±45° bevel capability for complex applications.

02/ 12000W MAX Laser source

The MAX MFSC series fiber laser adopts a modular design, delivering high integration and exceptional reliability for demanding tasks.

Moreover, it ensures maintenance-free operation and offers continuously adjustable power for superior beam quality and cutting stability.

In addition, the QBH head fiber output supports precise cutting and welding across various industrial applications.

Consequently, you benefit from world-class technology with a higher photoelectric conversion rate and outstanding light beam precision.

Furthermore, its higher energy density enhances cutting performance, while free maintenance guarantees the longest machine life and reduced downtime.

As a result, this advanced laser source maximizes productivity, improves efficiency, and ensures consistent results for complex manufacturing needs.

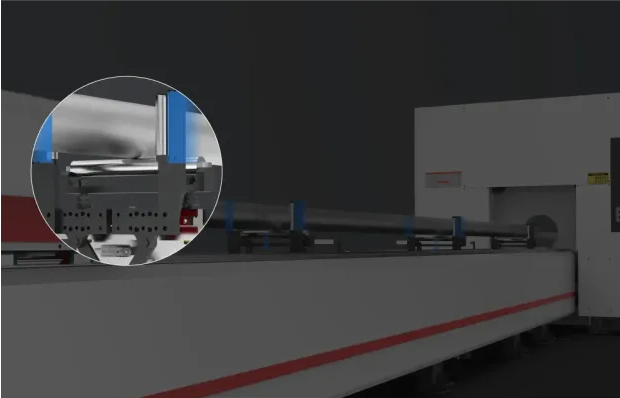

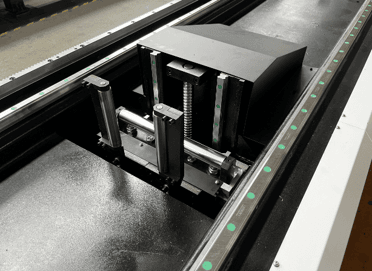

06/ Platform Servo support

The Laser tube cutting machine delivers exceptional precision and efficiency for heavy-duty applications. This advanced Laser tube cutting machine belongs to the HTG laser cutting machine tube series, designed to process tubes from 16mm to 350mm in diameter with ease.

Moreover, it cuts various profiles such as square, round, rectangular, oval, channel steel, H steel, and angle iron. In addition, the Laser Pipe Cutting machine uses a triple-chuck system with full-stroke pneumatic chucks and servo followers, ensuring stability and accuracy.

Furthermore, the Ospri autofocus cutting head guarantees consistent cutting height and automatic focus adjustment for drilling and cutting.

Consequently, the three-chuck zero tailing technology reduces material waste, enabling ultra-long tube cutting without leftover tails. As a result, this pipe laser cutting machine improves productivity, lowers costs, and delivers superior performance for complex applications.

09/ Hanli Water Chiller

Hanli Water Chiller is engineered to deliver reliable cooling for laser tube cutting machines. Its compact design saves valuable space while ensuring stable performance during continuous operation. This innovative structure supports high-speed cutting processes and maintains precision throughout production.

All components are sourced from trusted international and domestic brands, guaranteeing consistent quality, safety, and durability. The advanced cooling system effectively reduces thermal stress on laser pipe cutting machines, extending equipment lifespan and improving cutting accuracy. Every detail reflects a commitment to reliability and efficiency.

With a fully automatic control system, operation becomes smooth and effortless. The chiller integrates seamlessly with pipe laser cutting machines, offering precise temperature control for demanding industrial applications. By combining modern design and proven technology, Hanli provides an ideal solution for laser cutting machine tube operations, ensuring productivity and long-term performance.

10 / Strong Steel Tube Welded Machine Bed

The strong steel tube welded machine bed is built using high-quality raw materials to ensure durability and precision. After welding, it undergoes stress relief annealing for rough machining, followed by secondary vibration aging treatment. Finally, precision machining is completed on a large gantry milling machine to guarantee structural integrity.

To maintain accuracy, the guide rail surface and rack surface are processed and formed at the same time. This integrated approach ensures perfect alignment and consistent performance during high-speed operations, reducing errors and improving cutting efficiency.

These advanced design and processing methods provide excellent shock resistance, high rigidity, and stability.

The machine bed also offers good toughness, light weight, corrosion resistance, and oxidation resistance. Combined with superior structural strength, it supports high processing speed and long-term reliability, making it ideal for demanding industrial applications.

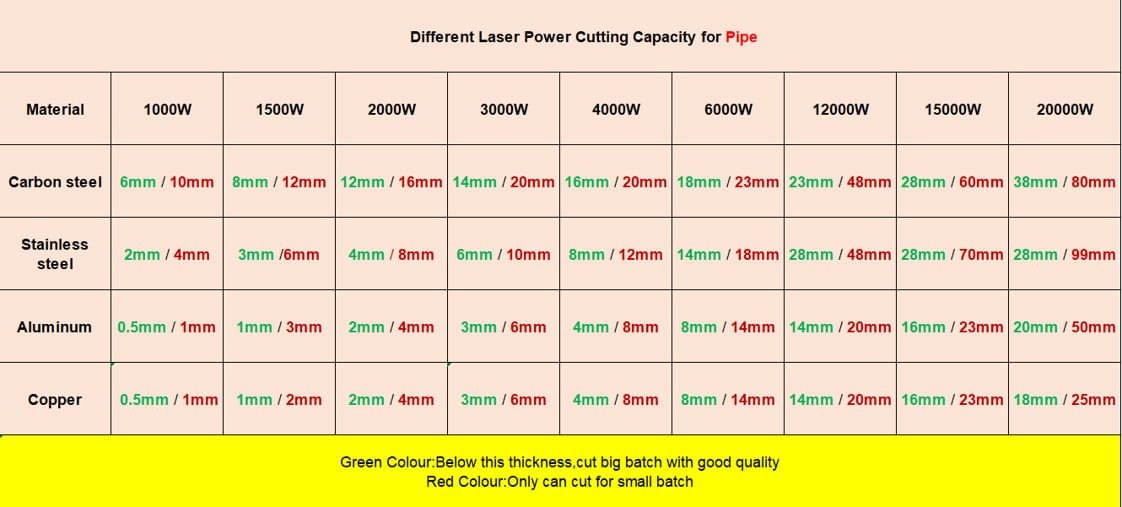

The Cutting Capacity of themachine

cutting Sample Showcase

Industrial Laser Cutting Application

Discover Our Full Range