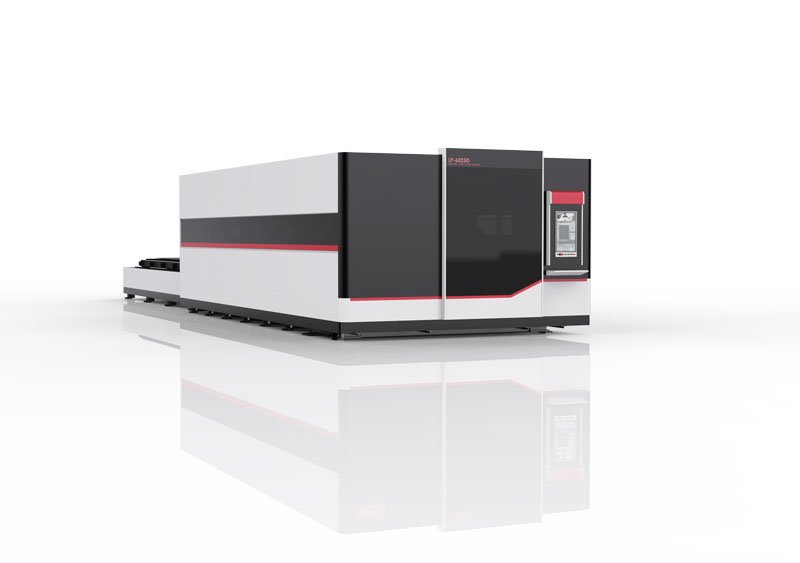

Plate Laser Cutting Machine -HTLP-6020D

The Plate Laser Cutting Machine sets a new benchmark in metal processing. This advanced plate laser cutting machine offers two power options: 6000W and 12000W, giving manufacturers flexibility to choose the best setup. It processes steel, aluminum, copper, and brass efficiently, making it suitable for industries that demand precision and speed.

Laser cutting technology plays a vital role in modern manufacturing. It enables accurate cuts while reducing material waste, improving productivity and cost efficiency. The HTLP-6020D laser sheet cutting machine delivers these benefits with precision and adaptability, helping businesses streamline workflows and maintain a competitive edge.

From automotive components to electronic housings, this metal sheet cutting machine ensures high-quality results. It supports various thicknesses, making it ideal for prototypes and large-scale production runs. Faster cutting speeds and lower operational costs make it a smart investment for manufacturers seeking growth and efficiency.

The HTLP-6020D Laser Metal Cutting Machine combines power, precision, and flexibility. As a leading laser metal cutter, it reinforces the role of laser technology in driving progress across the metal processing industry.

In summary, this advanced laser cutting solution empowers manufacturers to achieve superior performance, reduce costs, and enhance productivity. With its robust design and cutting-edge technology, the HTLP-6020D sets a new standard for efficiency and precision in metal fabrication.

key Advantage Of the plate Laser Cutting Machine

01/Cutting Ability

D series laser sheets cutting machine can cut metal sheets with a length of 3-12m, a width of 1.5-3.5m, and a thickness of less than 100mm;

02/Exchangeable platform

15S fast exchange, reducing the waiting time for cutting and loading, and effectively improving work efficiency by more than 30%.

03/Superior performance

Dual servo motor high dynamic drive, equipped with extruded aluminum beams, easily handle sheets of various thicknesses

04/Heavy-duty sheets welded bed

Mortise and tenon structure design, able to withstand greater loads. Laser cutting, large gantry milling machine one-time processing and forming, ensuring years of stable cutting

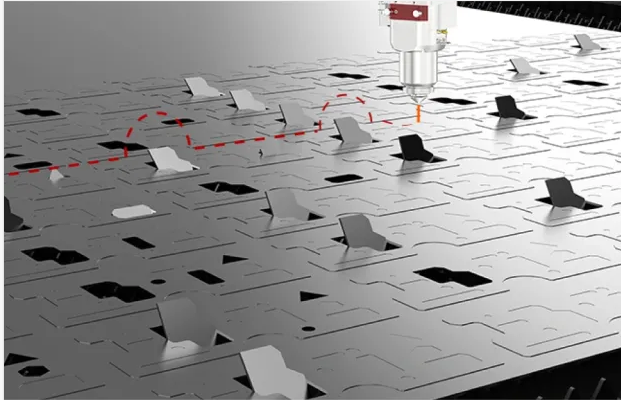

06/High-quality production

9 stage piercing, slag-free cutting, smooth micro-joint, intelligent fly-cut, automatic react, cutting path monitor and other complete intelligent processes to ensure efficient and high-quality production.

the Laser plate Cutting Machine Showcase

| Item | Specification |

|---|---|

| Performance Specification | |

| Max Cutting Size | 6000mm x 2500 mm |

| Max Load Capacity | 4500 Kg |

| Max Linkage Speed | 150m/min |

| Position Accuracy | ±0.03mm per Meter |

| Repeated Positoning Accuracy | ±0.02/1000mm |

| Max Accelerated Speed | 1.5 G |

| Working Environment | Tem: 0-40 oc Humidity 80% Less |

| Cutting Material | Carbon Steel, Stainless Steel , Aluminum , Copper, Galvanized Steel Plate etc |

| Mechanical Specification | |

| Control System | FSCUT 8000 Ethercat control system |

| HMI Pattern | Super Touch Screen |

| Cutting Software | FSCUT |

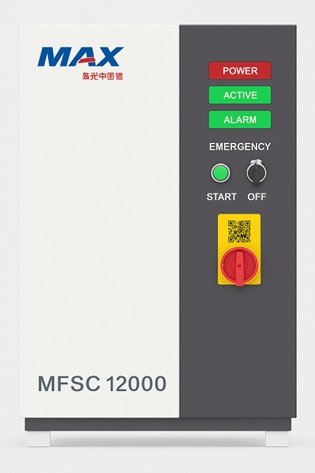

| Laser Source | MAX Laser Source-6000/ 12000W/40000W |

| Laser Cutting Head | Raytool /OSPRI /BOCI Laser Cutting Head |

| Cooling System | Hanli Water Chiller |

| Servos and Motor | China Inovance Ethercat Servo Motors |

| Reducer | Nidec ( shimpoo Reducer from Japan ) |

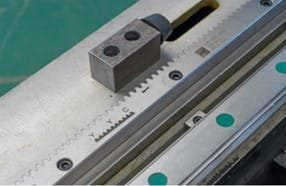

| Transmission System | YYC Rack and Pin, HIWIN Guide Rails |

| Bed Body | Heavy strong steel tube welded machine bed. All machine mounting groove and screw hole are milled by our Italy high precision GOLGAR milling center. |

| Gantry Structure | Cast Aluminum beam |

| Exchangible Bed Pallet | Yes |

| Electronic Parts | Schneide /Omron and Igus Cable |

| Hydraulic Parts | SMC/ AirTec Brand |

| Electric Control Cabinet | Independent |

| Parted Dust Removal System | Automatic Segmented , Draught fan 5.5 kw , 2800 RPM |

| Lubricated System | Automatic |

| Bevel Cutting | Optional |

| Power Supply | 380V, 50HZ±10% |

| Auxiliary Gas | Compressed air, Oxygen, Nitrogen |

| Valves | O2 Proportional Valve & N2 Proportional Valve |

| AC System | An Air Conditioner for Electric Cabinet |

The Unique User-Friendly Design

Key Features and Benefits

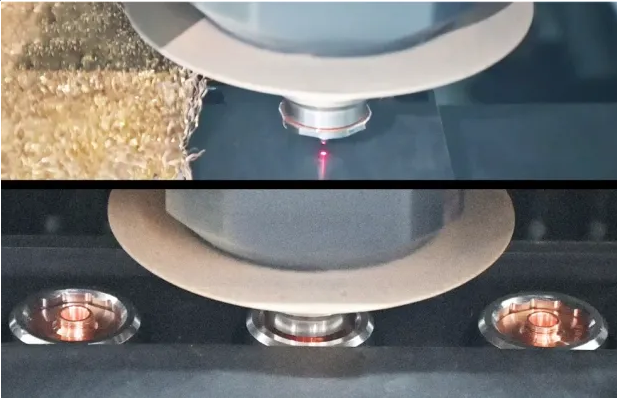

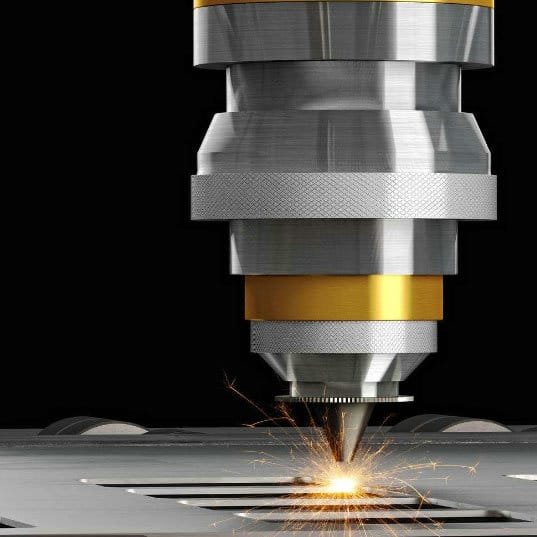

The Plate Laser Cutting Machine offers advanced design and precision for modern manufacturing. This plate laser cutting machine features an OSPRI/Roytool high-power cutting head, delivering fast and accurate cuts on steel, aluminum, copper, and brass. It boosts productivity while ensuring a flawless finish.

Interchangeable tables improve flexibility and reduce downtime. Operators can switch tables quickly for different material thicknesses, enabling smooth transitions between projects. This adaptability supports both small and large-scale production.

Safety is ensured by a patented smoke draft system that controls smoke and debris, creating a cleaner environment and improving visibility. The user-friendly touch-screen interface simplifies operation with intuitive icons, allowing beginners and experts to work efficiently.

The HTLP-6020D laser sheet cutting machine combines power, precision, and safety. As a leading Laser Metal Cutting Machine, it reinforces the role of the laser metal cutter in driving innovation across the

Advanced configuration of laser cutting machine

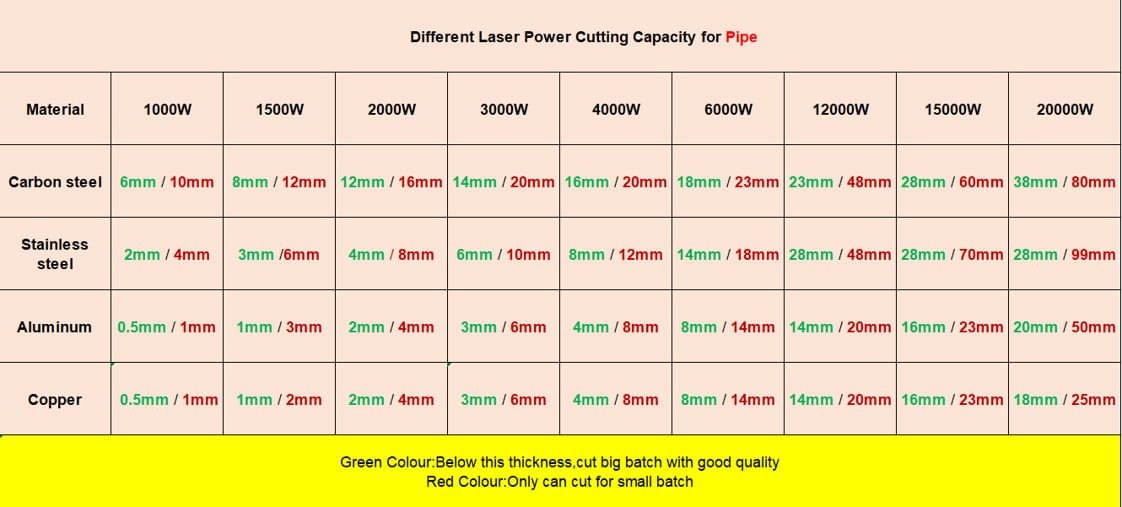

The Cutting Capacity of the Laser Plate cutting machine

Cutting quality Sample of the Metal laser cutting

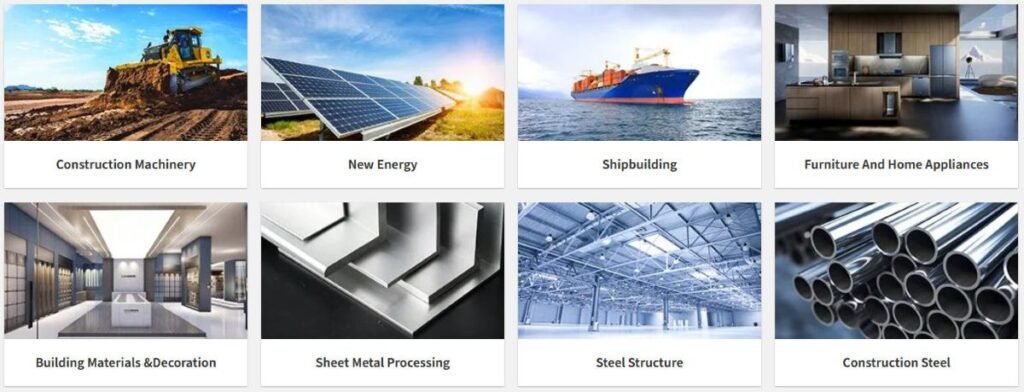

Industrial Laser Cutting Application

Discover Our Full Range