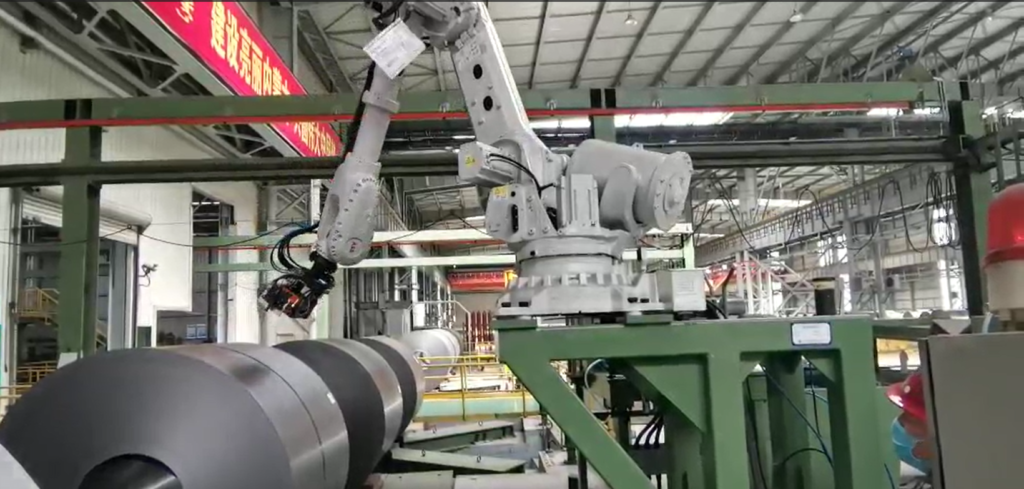

Robotic Steel Coil De-Bander System

Steel Coil De-bander is a breakthrough in coil processing. Our Steel Coil De-bander system automates strip removal and improves safety. This advanced Steel Coil De-banding System eliminates manual labor and reduces human error. It ensures precise and consistent handling of steel coils during packaging operations.

Moreover, the system integrates seamlessly with MES for full automation. As a result, production runs without human intervention, saving time and lowering costs. In addition, the six-axis robot and specialized removal mechanism efficiently cut and wind steel bands. These features minimize downtime and enhance productivity.

Furthermore, the Steel Coil De-banding System identifies coil diameter, width, and band position automatically. It performs band cutting, winding, and tape removal with remarkable accuracy. Consequently, operations become faster and safer while maintaining high-quality standards.

Because of its versatility, the system handles coils from 150 mm to 350 mm in diameter and widths from 800 mm to 1650 mm. This wide range supports various steel coil applications across industries.

Therefore, investing in the Steel Coil De-bander ensures optimized efficiency and reduced labor risks. It combines advanced robotics with intelligent control for unmatched performance.

Choose our Steel Coil De-banding System today to transform your coil processing into a smarter, safer, and more profitable operation. Partner with us to experience cutting-edge automation that drives growth and guarantees long-term success.

Robotic Steel Coil De-Bander System live Case

Discover Our Full Range