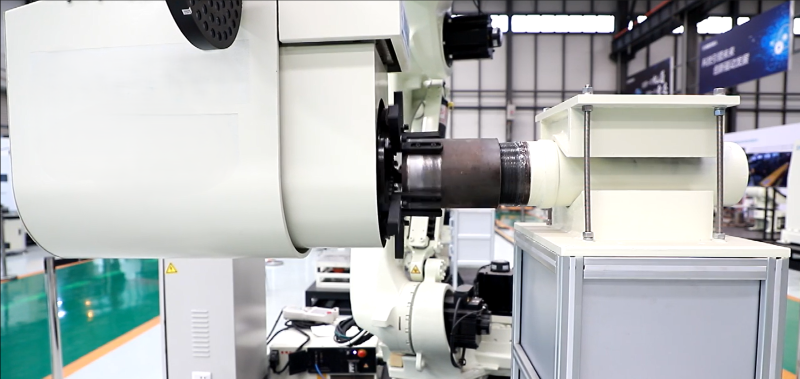

Robotic Coupling Starter System

Robotic Coupling Starter System is transforming pipe connection processes. The Robotic Coupling Starter System automates coupling tasks, reducing manual work and improving accuracy. This advanced solution integrates lubrication, pre-twisting, and screwing control for seamless performance. Moreover, the system performs offline lubrication without interrupting operations. As a result, it ensures optimal lubricant distribution and minimizes downtime.

Additionally, the robotic system uses a pre-twisting mechanism for precise torque application. It follows programmed parameters to guarantee consistent results according to industry standards.

Furthermore, the Robotic Coupling Starter System measures j-values and automates pre-screwing steps, improving connection integrity and reliability.

Automation reduces labor costs and enhances safety by eliminating repetitive tasks. Operators can focus on complex activities, boosting productivity and quality control. Embracing this technology streamlines workflows and supports smart manufacturing practices.

Upgrade your production line today to achieve precision, speed, and sustainability with this innovative Robotic Coupling Starter System. It delivers superior performance and creates a safer, more efficient working environment.

Robotic Coupling Stater Showcase

Discover Our Full Range