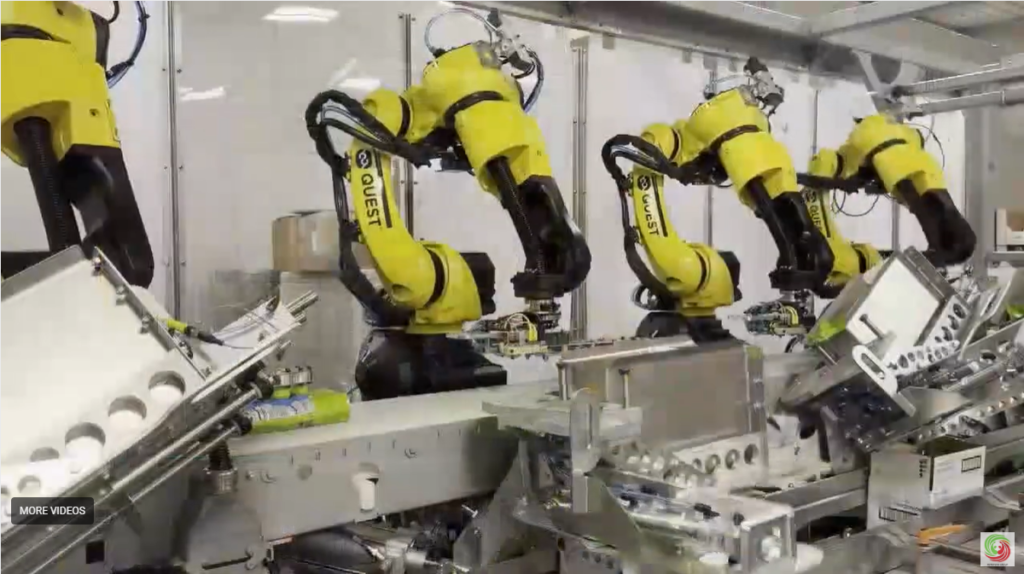

Packaging Automation Solution for small bags

Packaging Automation is transforming small bag packaging. This advanced Packaging Automation solution uses a high-speed 6-axis robot to boost efficiency. It handles up to 90 bags per minute, ensuring smooth operations and reducing manual labor. The system delivers consistent performance while maintaining product integrity.

One key advantage is flexibility and easy integration with existing production lines. The Packaging Automation solution adapts to various bag styles and sizes without costly reconfiguration. Manufacturers can meet diverse needs quickly and maintain high productivity. This versatility makes it ideal for dynamic production environments.

Efficiency is further enhanced through optimized packing patterns. Angled product buckets create vertical pack patterns for RSC and retail display cases. These patterns save space and protect products during transport. Additionally, the system supports flat pack patterns by adjusting tooling and removing buckets, offering unmatched adaptability.

Moreover, automation improves safety and reduces repetitive tasks. Businesses benefit from faster workflows, reduced downtime, and lower costs. By integrating advanced robotics, companies achieve operational excellence and stay competitive in the packaging industry.

In conclusion, the Packaging Automation solution combines speed, precision, and flexibility. It helps manufacturers optimize resources, enhance productivity, and deliver superior packaging results.

small Bags Packaging Automation Solution onsite

Discover Our Full Range