Aluminum Coil Products

Aluminum Coil is a versatile material widely used in modern industries. Aluminum Coil combines strength and light weight, making it ideal for automotive and construction applications. It also plays a key role in heat transfer systems and electrical equipment.

Manufacturers choose aluminum coils for their durability and adaptability. Standard thickness ranges from 0.045 mm to 80 mm, while widths reach up to 1500 mm. Custom sizes are available to meet specific production needs, ensuring flexibility for diverse projects.

Various alloy grades, including 1050,3003, 6061, and 5251, guarantee performance for different uses. These options allow manufacturers to select the right material for structural components or decorative finishes. Finishing treatments such as anodizing, brushing, and color coating enhance both appearance and functionality.

Compared to other materials, aluminum coils offer superior corrosion resistance and excellent thermal conductivity. They reduce overall weight without compromising strength, improving efficiency in transportation and building sectors. Pharmaceutical packaging also benefits from aluminum coils due to their hygienic properties.

With continuous innovation, aluminum coils remain a reliable choice for manufacturers seeking quality and versatility. Their ability to meet strict standards makes them essential for industries worldwide. This combination of features ensures aluminum coils will continue to support advanced production processes across multiple sectors.

Aluminum Coil Alloy Size

Specifications of Aluminum Coil

| Products Name | Aluminium Coil |

|---|---|

| Alloy/Grade | 1050, 1060, 1070, 1100, 1200, 2024, 3003, 3104, 3105, 3005, 5052, 5754, 5083, 5251, 6061, 6063, 6082, 7075, 8011, 8079, 802 |

| Temper | F, O, H |

| Thickness | 0.014mm-20mm |

| Width | 60mm-2650mm |

| Material | CC & DC route |

| Type | Strip, Coil |

| Standard | GB/T, ASTM, EN |

| Surface | Mill Finish, Anodized, Color coated PE Film Available |

| Packaging | Wooden Pallet for Strip & Coil |

Aluminum & Aluminum Alloy Grade

| Alloy Series | Alloy | Introduction |

|---|---|---|

| 1 Series | 1050 1060 1070 1100 | Industrial Pure Aluminum. Of all series, the 1000 series belongs to the series with the largest aluminum content. The purity can reach over 99.00%. |

| 2 Series | 2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17 | Aluminum-copper Alloys. 2000 series is characterized by high hardness, in which the content of copper is the highest, about 3-5%. |

| 3 Series | 3003 31053A21, 3003, 3103, 3004, 3005, 3105 | Aluminum-manganese Alloys. 3000 series aluminum sheet is mainly composed of manganese. The manganese content ranges from 1.0% to 1.5%. It is a series with a better rust-proof function. |

| 4 Series | 4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A | Al-Si Alloys. Usually, the silicon content is between 4.5 and 6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials, low melting points, and good corrosion resistance. |

| 5 Series | 5052, 5083, 5754, 5005, 5086,5182 | Al-Mg Alloys. 5000 series aluminum alloy belongs to the more commonly used alloy aluminum series, the main element is magnesium, and the magnesium content is between 3-5%. The main characteristics are low density, high tensile strength, and high elongation. |

| 6 Series | 6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 | Aluminum Magnesium Silicon Alloys. The representative 6061 mainly contains magnesium and silicon, so it concentrates on the advantages of the 4000 series and 5000 Series. 6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. |

| 7 Series | 7075, 7A04, 7A09, 7A52, 7A05 | Aluminum, Zinc, Magnesium, and Copper Alloys. The representative 7075 mainly contains zinc. It is a heat-treatable alloy, belongs to super-hard aluminum alloy, and has good wear resistance. 7075 aluminum plate is stress-relieved and will not deform or warp after processing. |

Surface Coating For Aluminum Coil

Introduction to Aluminum Coil Coatings

Surface coatings for aluminum coil play a crucial role in enhancing the durability and aesthetic appeal of aluminum products. Two popular types are fluorocarbon-coated (PVDF) and polyester-coated aluminum coils. Each coating has unique properties that cater to different applications, making them suitable for various environments.

Fluorocarbon Coatings: The Superior Choice

Fluorocarbon coatings primarily utilize PVDF resin, known for its exceptional chemical stability and durability. This type of coating features a strong fluorine/carbon bond, enhancing its resistance to abrasion and impact. Its ability to maintain color retention while withstanding harsh weather conditions makes it a preferred choice for outdoor decorations, commercial signage, and exhibition advertisements. Furthermore, the high-temperature curing process forms a tight molecular structure that significantly enhances the coating’s weather resistance

Polyester Coatings: Versatile and Vibrant

On the other hand, polyester-coated aluminum coils are formed through a multiple baking process, resulting in a protective film rich in aesthetic qualities. Incorporating anti-UV properties, polyester coatings are available in varying gloss levels, from matte to high-gloss. This versatility not only provides vibrant colors but also protects aluminum products against harsh environmental factors such as UV rays, rain, frost, and temperature variations. These coatings are particularly suitable for indoor decorations and advertising panels, adding depth and three-dimensionality to the finished products.

The Industrial Applications

Aluminum Deep Processing Services we Offer

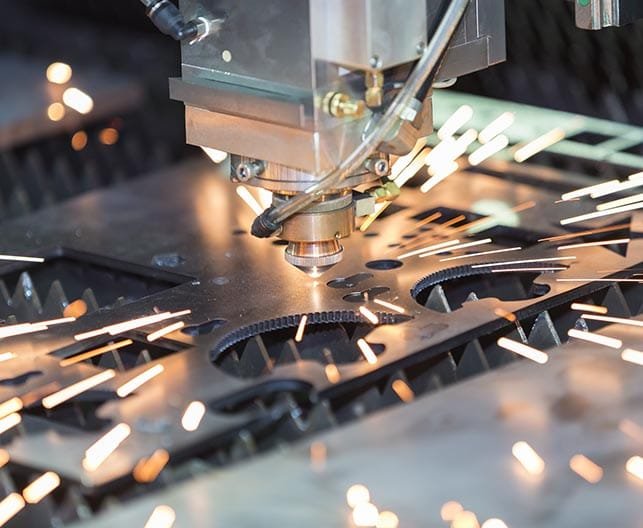

We provide advanced aluminum processing solutions tailored to your needs. Our services include precision cutting, Slitting, maching , casting , welding, and surface treatments such as anodizing, powder coating, and polishing. With state-of-the-art technology and strict quality control, we ensure superior accuracy, durability, and customization for diverse industrial applications

Discover Our Full Range