Plasma Pipe Cutting Machine for Intersection Line

Plasma pipe cutting machine delivers precision and speed for complex pipe intersections. This advanced plasma pipe cutter handles diameters from 30mm to 2000mm and lengths up to 12 meters. It supports low-carbon steel, stainless steel, copper, and aluminum, ensuring versatility for industrial applications.

The CNC system uses five-axis digital control for accurate axial and radial cuts. Dual servo motors enhance stability, while roller supports simplify loading and unloading. Operators benefit from smooth operation and minimal manual effort. The machine includes a robust H steel base, separate power chuck, and aligned guide rails for consistent accuracy.

Its gas supply system allows quick switching between cutting methods, improving efficiency. Designed for high productivity, this plasma pipe cutting machine ensures reliable performance and easy control for demanding projects.

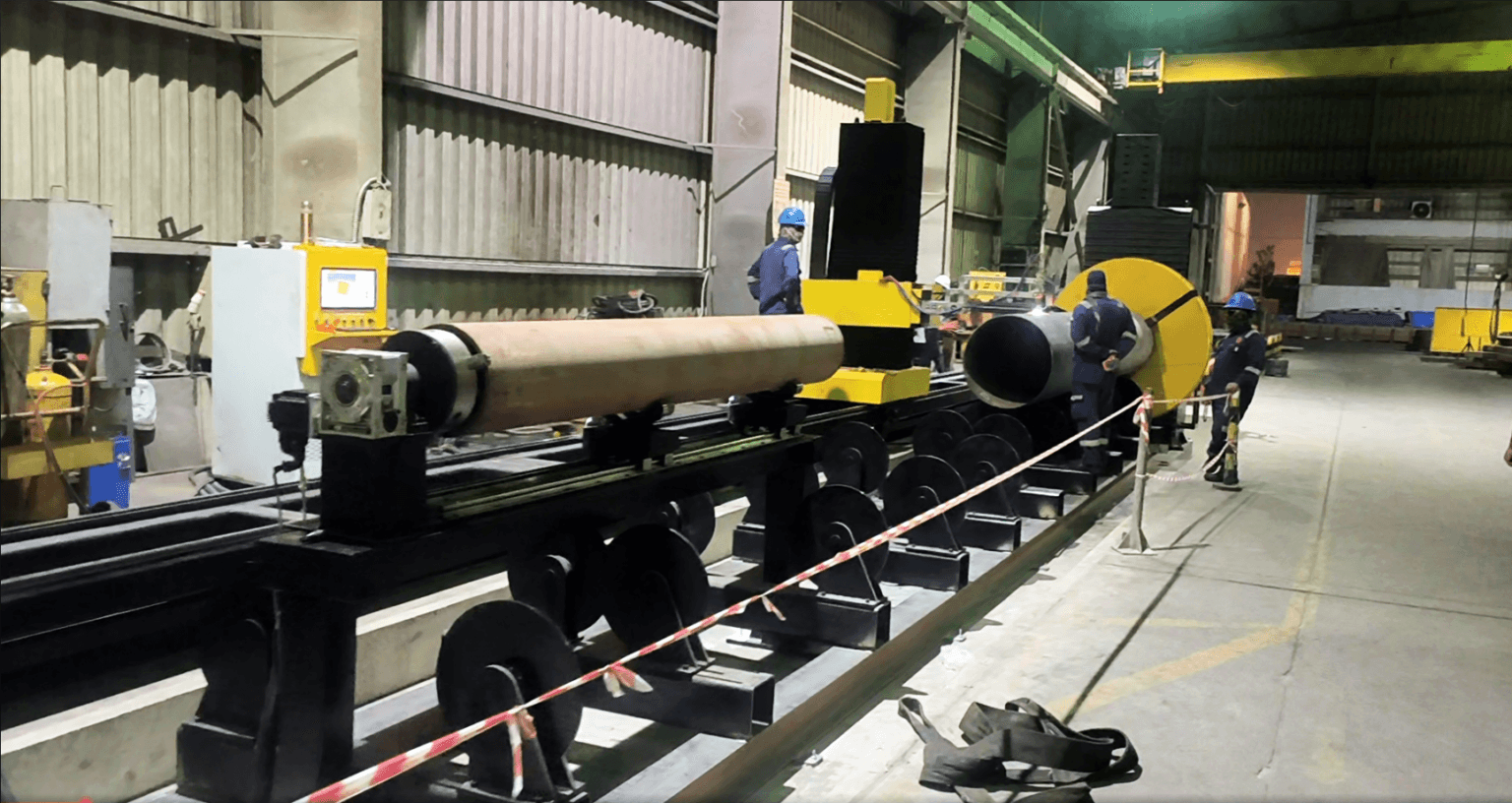

Plasma Pipe Cutting Machine Showcase

Specification of the plasma pipe cutting Machine

01 . Pipe Cutting Peformance

| Item | Specification |

|---|---|

| Pipe cutting Dia | 30-2000 mm |

| Max Cutting Thickness of Pipe wall by Flame | 300 mm |

| Max Cutting Thickness of Pipe wall by Plasma | 40 mm |

| Max Cutting pipe Length | 12000 mm |

| Max Load Capacity | 4000 Kg |

| Toch Motion Position Accuracy | ≤±0.03 mm |

| Processing Accuracy | 0.50-1.00 mm |

| Bevelling Motion Position Accuracy | ±0.05° |

| Bevelling Angle Range | 0-60° |

2. The Number of the Motion Axis and the Travel Range

| Motion Axis | Specification | Travel Range |

|---|---|---|

| Y-Axis | The cutting head moves along the longitudinal length of the workpiece. | 12500 mm |

| C-Axis | The cutting head is tilted radially around the cutting point on the workpiece surface. | A=±60° |

| Z-Axis | The cutting torch is raised and lowered vertically | Max 13000mm |

| R-Axis | Chuck rotates workpiece | 360 |

3. Cutting Speed of the pipe cutting machine

| Item | Specification |

|---|---|

| Flame cutting speed | 100-8000mm/min |

| Plasma cutting speed | 100-10000mm/min |

| Moving speed | 10-12000mm/min |

4. Equipment configuration

| Items | Specification |

|---|---|

| Torch Height control mode | Automatic ARC |

| Control System | EOE-5A |

| Servo Motors | Panasonic servo motor |

| Reducer | EOE |

| Software | EOE-HZH |

| Plasma Source | LGK-200A |

| Chuck Supporter | 300-2000 mm |

| Raise and Down Ball screw | TBI 25 mm |

| Support Roller System | 20×24 kgs |

5. Working Environment Requirement

1) Ambient temperature: -10-50℃

(2) Ambient humidity: monthly average humidity ≤80%

(3) Power supply: The power input of the control system is 220V±10% 50HZ + 380V± 10%50Hz

(4) Air source: flame available oxygen + acetylene or oxygen + propane (preheating oxygen ≥0.7Mpa, cutting oxygen ≥ 1Mpa, gas ≥0.05Mpa)

(5) Protection gas: air, oxygen, pressure 8.3bar, flow rate 0.36 cubic meters/min

(6) Installation site: indoor installation, concrete foundation, the Ground should be flat, the inclination is not more than 1/100

working Sample Showcase

Discover Our Full Range