Laser Cutting Machine For Metal Sheet HTSB-3015

The HTSB-3015 laser cutting machine for metal sets a new benchmark in modern fabrication. This advanced laser metal cutting machine combines precision and speed, enabling manufacturers to achieve superior results with minimal effort.

By using cutting-edge laser technology, it delivers clean, accurate cuts that outperform traditional methods. Businesses adopting this solution gain a competitive edge through faster production and consistent quality.

One major advantage is its expansive cutting area, which supports large sheets and complex designs without manual repositioning. This feature reduces setup time and increases efficiency, allowing smooth transitions between tasks. As a result, companies can handle high-volume projects while maintaining accuracy and reducing operational delays.

Automation is another key strength of this laser cutting machine for metal. Integrated material loading and unloading systems minimize labor costs and human error. Real-time monitoring and smart diagnostics improve maintenance and reduce downtime, ensuring continuous productivity. These innovations make the HTSB-3015 an ideal choice for manufacturers seeking reliability and performance.

By combining speed, precision, and automation, this laser metal cutting machine transforms traditional workflows into streamlined operations. It empowers businesses to deliver intricate components quickly and maintain high standards of quality. Investing in this technology means staying ahead in today’s competitive market.

key Advantage Of the Laser Cutting Machine For metal Sheet

01/Cutting Ability

Economical laser cutting machine S series, can cut metal sheets with the length of 3-10 meters, the width of 1.5-3.5m, and the thickness 100mm or less;

02/low operating Cost

less initial investment, small footprint, low energy consumption, low maintenance cost, high cutting efficiency. It is the best choice for enterprises to achieve economic operation!

03/Efficient cutting

1.5G acceleration, 150m/min moving speed and advanced CNC technology can greatly improve your production efficiency

04/Easy Operation

With intelligent interface, high degree of automation, real-time monitoring and automatic adjustment, simplifying operation and making it easier to get started;

06/Easy maintenance

1Modular design, simple structure, few fault points, can quickly locate problems without large-scale disassembly and repair.

Laser Cutting Showcase

Key Features of the laser cutting machine for metal Sheet

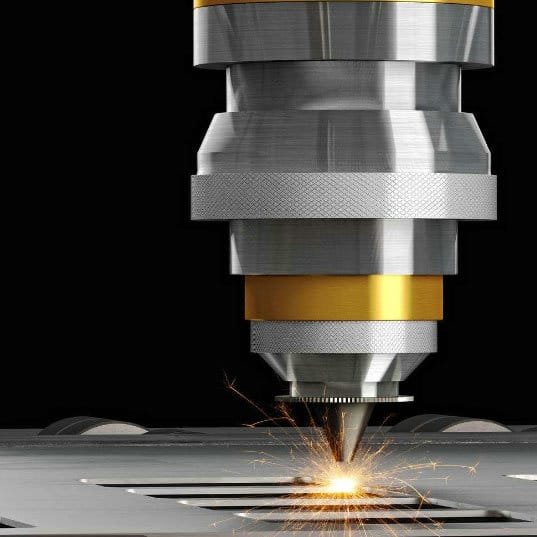

The HTSB-3015 laser cutting machine for metal delivers precision and efficiency for modern fabrication. This advanced laser metal cutting machine offers customizable power options, enabling operators to adjust cutting strength for different materials. Whether cutting thin sheets or thick plates, it ensures clean cuts and reduces waste, improving productivity and flexibility.

Moreover, its robust gantry structure provides stability and minimizes vibrations, guaranteeing consistent cutting lines for strict tolerances. Combined with advanced laser technology, the machine produces intricate designs and smooth edges across various thicknesses, making it a reliable solution for diverse applications.

Additionally, user-friendly software simplifies design and cutting processes. Operators can upload files, set parameters, and monitor performance in real time, reducing downtime and enhancing workflow. These features make the HTSB-3015 an ideal laser cutting machine for metal industries seeking speed, accuracy, and ease of use.

Specification of the Laser Plate Cutting Machine

| Item | Specification |

|---|---|

| Performance Specification | |

| Max Cutting Size | 3000mm x 1500 mm |

| Max Load Capacity | 700 Kg |

| Max Linkage Speed | 120m/min |

| Position Accuracy | ±0.03mm per Meter |

| Repeated Positoning Accuracy | ±0.02/1000mm |

| Max Accelerated Speed | 1.5 G |

| Working Environment | Tem: 0-40 oc Humidity 80% Less |

| Cutting Material | Carbon Steel, Stainless Steel , Aluminum , Copper, Galvanized Steel Plate etc |

| Mechanical Specification | |

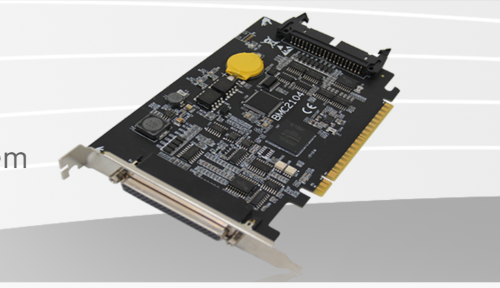

| Control System | FSCUT2000E |

| HMI Pattern | Super Touch Screen |

| Cutting Software | FSCUT |

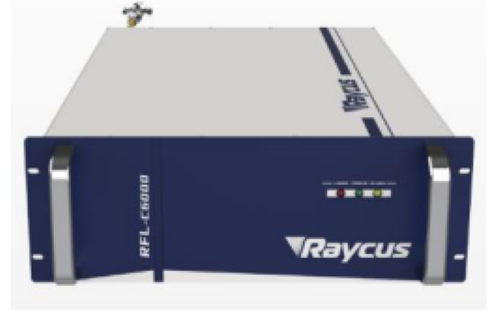

| Laser Source | Raycus3000w |

| Laser Cutting Head | Raytool Auto Focus Cutting Head |

| Cooling System | S&A Water-Cooled Chiller |

| Servos and Motor | Yaskawa Servo Motor system |

| Reducer | Nidec ( shimpoo Reducer from Japan ) |

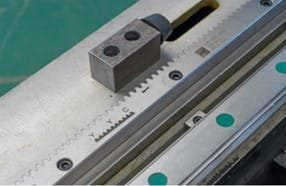

| Transmission System | YYC Rack and Pin, HIWIN Guide Rails |

| Bed Body | Tube-welded,Excellent engineered ,Stress-Relieved |

| Gantry Structure | Cast Aluminum beam |

| Exchangible Bed Pallet | Optional |

| Electronic Parts | Schneide /Omron and Igus Cable |

| Hydraulic Parts | SMC/ AirTec Brand |

| Electric Control Cabinet | Independent |

| Parted Dust Removal System | Automatic Segmented , Draught fan 5.5 kw , 2800 RPM |

| Lubricated System | Automatic |

| Bevel Cutting | Optional |

| Power Supply | 380V, 50HZ±10% |

| Auxiliary Gas | Compressed air, Oxygen, Nitrogen |

| Valves | O2 Proportional Valve & N2 Proportional Valve |

| AC System | An Air Conditioner for Electric Cabinet |

Advanced configuration of laser cutting machine

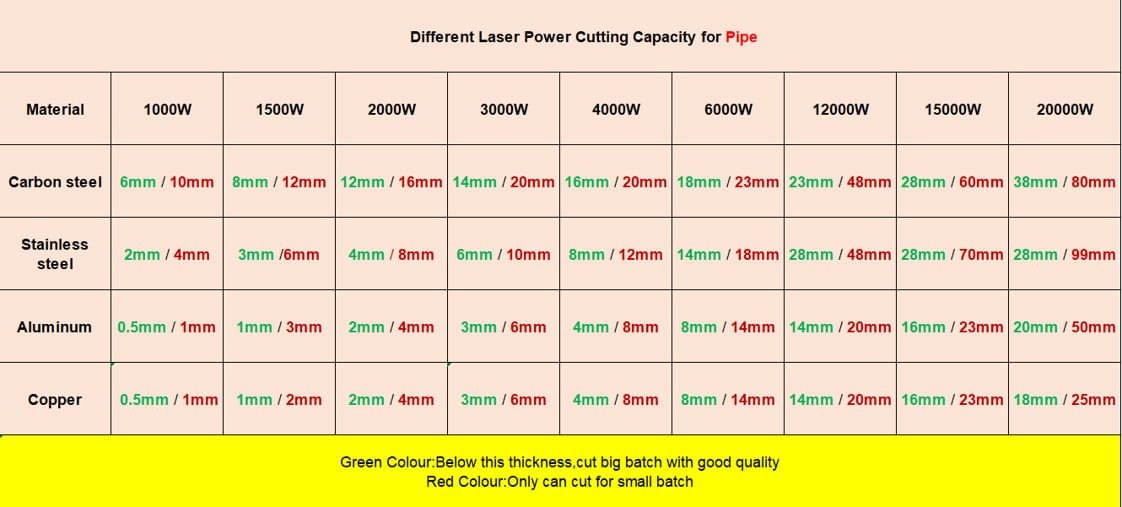

The Metal Sheet Cutting Capacity of the laser cutter

Cutting quality Sample of the Metal laser cutting

Industrial Laser Cutting Application

Discover Our Full Range