Coupling Threading Machine

Our Coupling Threading Machine is a high-end CNC solution designed to deliver exceptional performance in the metallurgical steel pipe industry. By integrating global advanced technologies, we have developed a machine equipped with a flip chuck for superior efficiency and precision. This Coupling Threading Machine ensures fast, accurate, and large-scale threading of oilfield coupling materials, meeting the highest standards of automation and productivity.

The machine supports multiple thread types, including short round, long round, buttress, and special premium threads compliant with API 5CT and 5B standards. It is engineered to process various steel grades such as J55, N80, L80, C90, P110, and Q125, making it versatile for diverse production needs. Additionally, customers can choose from globally recognized CNC systems like FANUC or Siemens for enhanced control and operational flexibility.

With advanced automation, high precision, and outstanding efficiency, this Coupling Threading Machine—also known as a Coupling Threader, Coupler Threading Machine, or Coupling Threading Lathe—helps manufacturers reduce costs while increasing throughput. It is the ideal solution for oilfield pipe threading operations that demand reliability and consistency.

Main Features of the CNC Pipe Threading Machine

Our CNC Coupling threading machine is designed for precision and efficiency, making it the ideal solution for high-performance pipe processing. This CNC Coupling threading machine integrates advanced global design concepts with superior rigidity and accuracy, ensuring exceptional results for OCTG and steel coupling threading applications

01. Innovative Design Concep

The machine features advanced design inspired by world-class products, delivering exceptional precision and efficiency for superior performance in demanding environments.

02. High Rigidity Structure

This lathe features a 45° slant bed, large-diameter spindle, and tapered roller bearings with high load capacity, ensuring stability during heavy-duty cutting. Users gain consistent accuracy and extended machine life.

03. Superior Precision

Equipped with precision bearings, advanced feed components, and a rigid box-type base, the machine delivers superior accuracy, stable positioning, and long-term reliability—surpassing domestic standards and rivaling imported models.

04. Structural Highlights

The CNC pipe threading machine includes a hydraulic flip chuck and a four-position vertical hydraulic or servo turret for complete coupling processing in one setup. Its drive system combines a servo-driven spindle with belt transmission and a precision feed system using ball screws and steel-inlaid guideways..

05. Automation & Smart

The CNC pipe threading machine integrates six-axis robotic arms, gantry loaders, material handling stations, and AGV transfer systems, enabling fully automated production—from raw material loading to threading, inspection, and packaging—supporting minimal manpower or even unmanned operation for maximum efficiency.

06.Efficiency and Performance

By optimizing rigidity, strength, wear resistance, and vibration damping, and applying a multi-tooth comb cutter process, this OCTG pipe threading machine ensures powerful, efficient threading. It supports low-speed, high-torque cutting, high metal removal rates, and fast cycles for reliable, productive performance.

07.High Reliability and Easy Maintenance

Critical components, including bearings, hydraulic systems, lubrication, cooling, belts, electrical parts, and ball screws, are sourced from leading global brands. This ensures stable operation, enhances reliability, and significantly reduces maintenance costs for the CNC pipe threading lathe.

08.Advanced Control and User-Friendly Interface

The machine is equipped with Siemens 840D or FANUC CNC systems, providing intuitive controls and an ergonomic interface. Advanced software functions further enhance the operator experience, simplifying complex operations and improving overall efficiency and productivity.

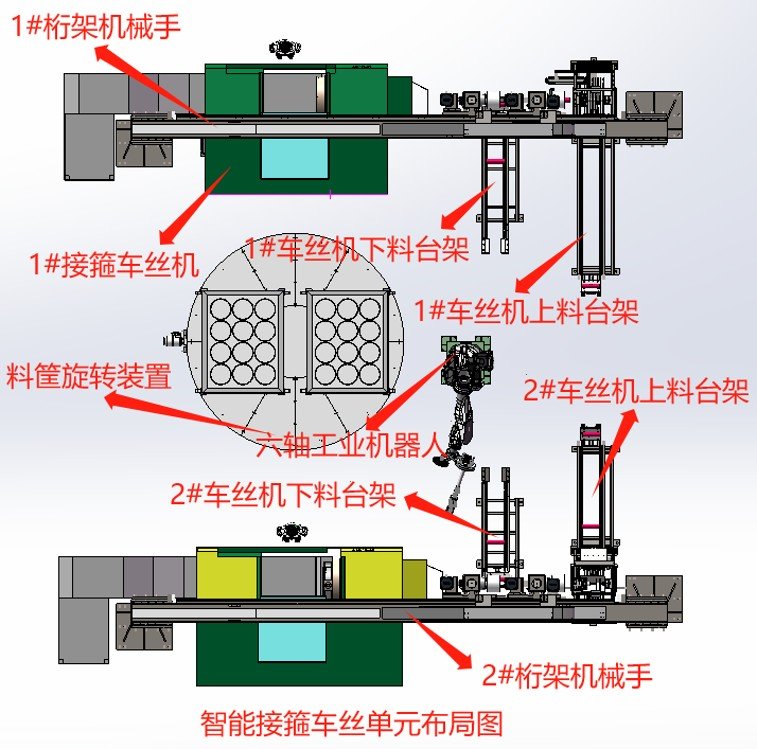

The Composition of the coupling threading unit

Each threading unit consists of two main machines, two gantry loaders with auxiliary loading/unloading devices, and one six-axis industrial robot with integrated fixtures and accessories. This configuration ensures seamless material handling, precise threading operations, and high automation efficiency, making it ideal for modern oilfield coupling production lines.

| No | Item | Qty |

|---|---|---|

| 1 | 6-Axis Robotic System | 1 Set |

| 2 | Rotating Material Basket Device | 1 Set |

| 3 | Gantry Manipulator System | 2 Set |

| 4 | Gantry Loading Bench | 2 Set |

| 5 | Gantry Unloading Bench | 2 Set |

| 6 | cnc Coupling Threading machine | 2 Set |

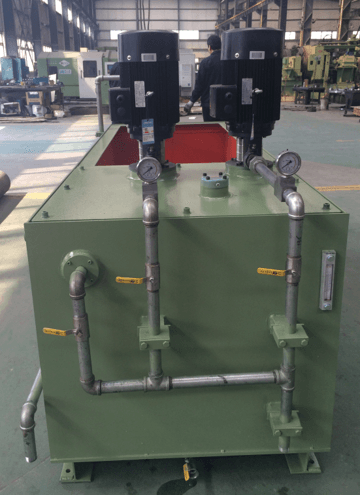

| 7 | Hydraulic System | 2 Set |

| 8 | Lubricating System | 2 Set |

| 9 | Emulsion Cooling System | 2 Set |

| 10 | Chip Conveyors | 2 Set |

| 11 | Control System | 2 Set |

Specification of the pipe Coupling Threading Machine

This machine is designed for processing tubes with diameters ranging from 2 3/8″ to 7″

coupling Threading Machine Performance

| Item | Unite | Specification |

|---|---|---|

| Processed Tube Dia | Inch | 2 3/8″-7′ |

| Max Coupling Turning Length | mm | 400/ |

spindle system

| Item | Unite | Specification |

|---|---|---|

| Max Spindle Speed | Rpm | 1000 |

| Spindle Motor | Kw | 60 |

| Spindle Through Hole Dia | mm | 150 |

| Spindle end shape and code | – | A2-11 |

Swivel Chuck System

| Item | Unite | Specification |

|---|---|---|

| Outside Diameter | mm | 770 |

| Height | mm | 464 |

| Clamping Stroke | mm | 12(9+3) |

| Number of Jaws | Pcs | 10(7+3) |

coupling Threading machine Turret System

| Item | Unite | Specification |

|---|---|---|

| Turret Pattern | – | Vertical Hydraulic Turret |

| Stations | Station | 4 |

| Height of Center | mm | 200 |

| Max Torque | Nm | 250 |

| Repeated Position Accuracy | mm | ≤0.005 |

X- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| X axis Travel | mm | 450 |

| Balance cylinder balance pressure | 30 |

z- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| Z axis Travel | mm | 450 |

| X/Z Axis Fast Speed | m/min | 15/15 |

Hydraulic system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4 Kw |

| Pump Flow | L/Min | 28 |

| Working Pressure | Bar | 60 |

| Hydraulic Oil tank Capacity | L | 200 |

| Accumulator capacity | L | 20 L ( 35bar ) |

Machine cooling system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4KW-2P-50HZ |

| Pump Flow | L/Min | 66 |

| Working Pressure | Bar | 20-25 Bar |

| Cooling Tank Capacity | L | 1000 |

| Filter fineness | um | 50 |

centralized Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Pump Flow | L/Min | 0.15 |

| Working Pressure | Bar | 20-25 Bar |

| Oil Tank Capacity | L | 3-5 L |

Spindle Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Motor Power | KW | 0.15 |

| Pump Flow | L/Min | 24 |

| Working Pressure | Bar | 3-5 Bar |

Control System

| Item | Unite | Specification |

|---|---|---|

| Nc Control System | – | Siemens 840 Ds1 |

This machine is designed for processing tubes with diameters ranging from 4 1/2″-9 5/8′

coupling Threading Machine Performance

| Item | Unite | Specification |

|---|---|---|

| Processed Tube Dia | Inch | 4 1/2″-9 5/8′ |

| Max Coupling Turning Length | mm | 400 |

spindle system

| Item | Unite | Specification |

|---|---|---|

| Max Spindle Speed | Rpm | 800 |

| Spindle Motor | Kw | 71 |

| Spindle Through Hole Dia | mm | 195 |

| Spindle end shape and code | – | A2-15 |

Swivel Chuck System

| Item | Unite | Specification |

|---|---|---|

| Type | – | Hydraulic Swivel Chuck |

| No of Jaws | mm | 6 (3 Centering Jaws ,3 Floating Jaws) |

| Clamping Pressure (adjustment Range) | Bar | 15-40 |

Turret System

| Item | Unite | Specification |

|---|---|---|

| Turret Pattern | – | Vertical Hydraulic Turret |

| Stations | Station | 4 |

| Height of Center | mm | 200 |

| Max Torque | Nm | 250 |

| Repeated Position Accuracy | mm | ≤0.005 |

X- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| X axis Travel | mm | 600 |

| Balance cylinder balance pressure | 30 |

z- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| Z axis Travel | mm | 600 |

| X/Z Axis Fast Speed | m/min | 15/15 |

Hydraulic system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4 Kw |

| Pump Flow | L/Min | 28 |

| Working Pressure | Bar | 60 |

| Hydraulic Oil tank Capacity | L | 200 |

| Accumulator capacity | L | 20 L ( 35bar ) |

cooling system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4KW-2P-50HZ |

| Pump Flow | L/Min | 66 |

| Working Pressure | Bar | 20-25 Bar |

| Cooling Tank Capacity | L | 1000 |

| Filter fineness | um | 50 |

centralized Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Pump Flow | L/Min | 0.15 |

| Working Pressure | Bar | 20-25 Bar |

| Oil Tank Capacity | L | 3-5 L |

Spindle Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Motor Power | KW | 0.15 |

| Pump Flow | L/Min | 24 |

| Working Pressure | Bar | 3-5 Bar |

Control System

| Item | Unite | Specification |

|---|---|---|

| Nc Control System | – | Siemens 840 Ds1 |

This machine is designed for processing tubes with diameters ranging from 4 1/2“-13 3/8”

coupling Threading Machine Performance

| Item | Unite | Specification |

|---|---|---|

| Processed Tube Dia | Inch | 4 1/2“-13 3/8” |

| Max Coupling Turning Length | mm | 400 |

spindle system

| Item | Unite | Specification |

|---|---|---|

| Max Spindle Speed | Rpm | 600 |

| Spindle Motor | Kw | 45 |

| Spindle Through Hole Dia | mm | 195 |

| Spindle end shape and code | – | A2-15 |

Swivel Chuck System

| Item | Unite | Specification |

|---|---|---|

| Outside Diameter | mm | 865 |

| Height | mm | 509 |

| Clamping Stroke | mm | 10(7+3) |

| Number of Jaws | Pcs | 10(7+3) |

Turret System

| Item | Unite | Specification |

|---|---|---|

| Turret Pattern | – | Vertical Hydraulic Turret |

| Stations | Station | 4 |

| Height of Center | mm | 200 |

| Max Torque | Nm | 250 |

| Repeated Position Accuracy | mm | ≤0.005 |

X- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| X axis Travel | mm | 600 |

| Balance cylinder balance pressure | 30 |

z- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| Z axis Travel | mm | 600 |

| X/Z Axis Fast Speed | m/min | 15/15 |

Hydraulic system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4 Kw |

| Pump Flow | L/Min | 28 |

| Working Pressure | Bar | 60 |

| Hydraulic Oil tank Capacity | L | 200 |

| Accumulator capacity | L | 20 L ( 35bar ) |

cooling system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4KW-2P-50HZ |

| Pump Flow | L/Min | 66 |

| Working Pressure | Bar | 20-25 Bar |

| Cooling Tank Capacity | L | 1000 |

| Filter fineness | um | 50 |

coupling Threading Machine centralized Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Pump Flow | L/Min | 0.15 |

| Working Pressure | Bar | 20-25 Bar |

| Oil Tank Capacity | L | 3-5 L |

Spindle Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Motor Power | KW | 0.15 |

| Pump Flow | L/Min | 24 |

| Working Pressure | Bar | 3-5 Bar |

Control System

| Item | Unite | Specification |

|---|---|---|

| Nc Control System | – | Siemens 840 Ds1 |

This machine is designed for processing tubes with diameters ranging from 9 5/8“ -20”

coupling Threading Machine Performance

| Item | Unite | Specification |

|---|---|---|

| Processed Tube Dia | Inch | 9 5/8“ -20” |

| Max Coupling Turning Length | mm | 400 |

spindle system

| Item | Unite | Specification |

|---|---|---|

| Max Spindle Speed | Rpm | 600 |

| Spindle Motor | Kw | 75 |

| Spindle Through Hole Dia | mm | 195 |

| Spindle end shape and code | – | A2-15 |

Turret System

| Item | Unite | Specification |

|---|---|---|

| Turret Pattern | – | Vertical Hydraulic Turret |

| Stations | Station | 4 |

| Height of Center | mm | |

| Max Torque | Nm | 250 |

| Repeated Position Accuracy | mm | ≤0.005 |

X- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| X axis Travel | mm | 600 |

| Balance cylinder balance pressure | 30 |

z- axis Feeding System

| Item | Unite | Specification |

|---|---|---|

| Z axis Travel | mm | 600 |

| X/Z Axis Fast Speed | m/min | 15/15 |

Hydraulic system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4 Kw |

| Pump Flow | L/Min | 28 |

| Working Pressure | Bar | 60 |

| Hydraulic Oil tank Capacity | L | 200 |

| Accumulator capacity | L | 20 L ( 35bar ) |

cooling system

| Item | Unite | Specification |

|---|---|---|

| Hydraulic Pump Motor | Kw | 4KW-2P-50HZ |

| Pump Flow | L/Min | 66 |

| Working Pressure | Bar | 20-25 Bar |

| Cooling Tank Capacity | L | 1000 |

| Filter fineness | um | 50 |

centralized Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Pump Flow | L/Min | 0.15 |

| Working Pressure | Bar | 20-25 Bar |

| Oil Tank Capacity | L | 3-5 L |

Spindle Lubricating System

| Item | Unite | Specification |

|---|---|---|

| Motor Power | KW | 0.15 |

| Pump Flow | L/Min | 24 |

| Working Pressure | Bar | 3-5 Bar |

Control System

| Item | Unite | Specification |

|---|---|---|

| Nc Control System | – | Siemens 840 Ds1 |

Main Structural and Performance Features

01. Coupling Threading machine Bed

The Coupling Threading Machine features a 45° slant bed made of high-performance cast iron, annealed twice for rigidity and precision retention. Its ribbed closed-frame resists bending and torsion, while hardened steel-inlaid guideways reach Shore 70° hardness.

The integrated box-type base and spindle lubrication box prevent oil leakage. These structural advantages ensure cutting stability and long-term accuracy, making the Coupling Threading Machine—also called Coupling Threader or Coupling Threading Lathe—ideal for demanding oilfield and OCTG applications.

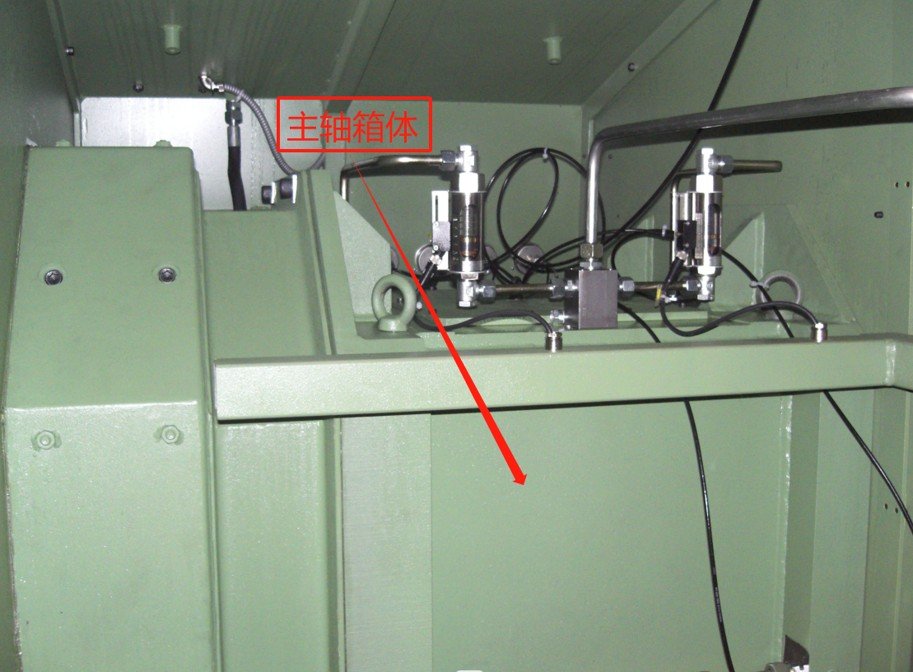

02. coupling Threading machine Spindle Box

The Coupling Threading Machine uses Q345-A steel plates for major components like the spindle box. Advanced pre-weld treatment, precise welding, heat treatment, and machining eliminate stress, while steel’s higher elastic modulus ensures superior rigidity compared to cast iron.

The spindle features a large through-hole design with imported tapered roller bearings, hydraulic oil cooling, and lubrication, delivering excellent rigidity, low temperature rise, and high accuracy. With these advantages, the Coupling Threading Machine—also called Coupling Threader or Coupling Threading Lathe—provides reliable performance for demanding oilfield threading operations.

03. Slide And Carriage

The Coupling Threading Machine uses hardened steel-inlaid guideways (over 60 HRC) and injection-molded sliding surfaces for low friction, high rigidity, and superior vibration absorption.

Friction performance exceeds conventional plastic processes, with stiffness close to steel-to-steel contact for heavy-duty cutting. A hydraulic balance cylinder offsets slide and turret weight, enhancing stability. These features ensure smooth motion, durability, and reliable performance for demanding oilfield threading operations.

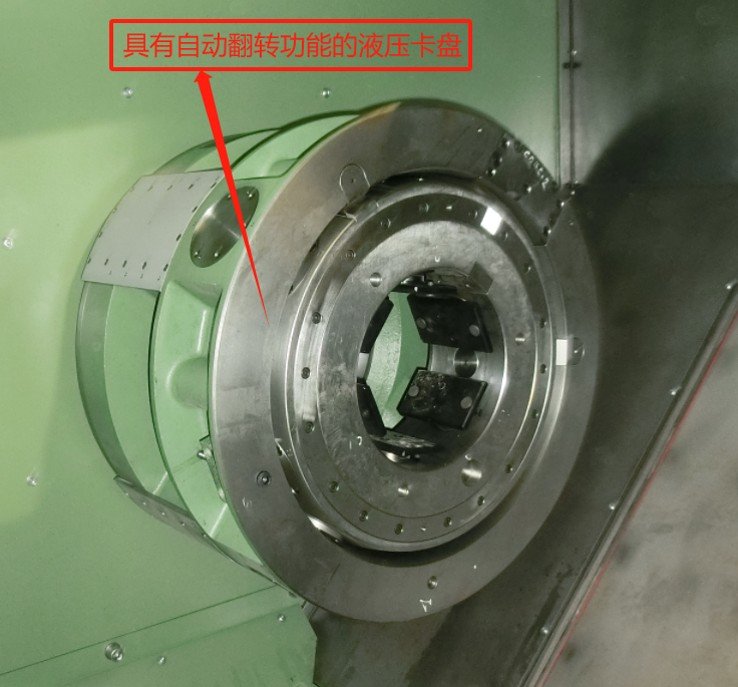

04. X/Z feeding System

The Coupling Threading Machine features a hydraulic swivel chuck that enables complete machining of both internal surfaces and end faces in one clamping. After machining the first side, the chuck rotates 180° for the second side without re-clamping.

It offers high rotation accuracy and adjustable clamping force—strong for rough boring, lighter for finish threading to prevent deformation. This design is ideal for large-diameter, high-strength couplings, ensuring precise thread alignment. With these advantages, the Coupling Threading Machine delivers superior flexibility, precision, and reliability for demanding oilfield threading operations.

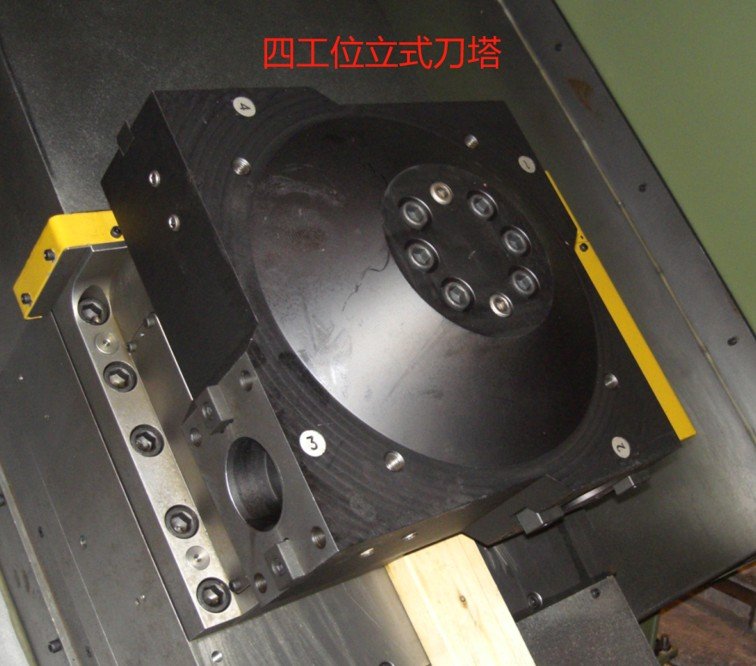

05. Four Position Turret System

The Coupling Threading Machine features a high-grade vertical four-position hydraulic turret, designed for heavy cutting and high precision. It offers a compact structure, fast rotation, strong locking force, and excellent load capacity.

Precision indexing uses a hardened large-diameter end-tooth disc for accurate positioning, while proximity switches ensure reliable signal transmission to the PLC system. Hydraulic cylinder locking provides powerful clamping, enhancing heavy-duty cutting capability. With these advantages, the Coupling Threading Machine delivers stable performance, precise tool positioning, and high reliability for demanding oilfield threading operations.

06.Machine Lubricating System

The Coupling Threading Machine uses a centralized lubrication system for the feed axis, covering guideways, wedge blocks, and ball screws. This open, total-loss system mixes lubricant with coolant and drains away, with PLC-controlled oil cycles and flow detection for safety.

The spindle unit employs a motor-driven pump for forced lubrication and cooling via a pressure spray circulation system, monitored by filtration and electronic flow switches. The gantry loader features automatic centralized grease lubrication. All systems include liquid level alarms, ensuring reliable operation and protection for demanding oilfield threading environments.

07. High‑Pressure Coolant System

The CNC pipe threading machine features a high-pressure, high-flow coolant system that delivers emulsion directly through the tool head and tool-bar channels. This design targets the cutting edge for rapid cooling, extended tool life, and superior thread quality. A chip conveyor with a return pump filters and recycles coolant, while a level-monitoring device ensures consistent and stable operation during high-volume machining.

08.Independent Hydraulic System

The CNC pipe threading lathe is equipped with an independent hydraulic pump station that powers all hydraulic functions of the machine and its loading platform. A valve block mounted on the headstock precisely controls chuck clamping, centering, the stop device, and Turret balancing for smooth operation. Integrated monitoring of oil level, pressure, and temperature ensures consistent performance and prevents system failures.

This robust hydraulic system delivers reliability and stability, meeting the demanding requirements of OCTG pipe threading applications and supporting high-volume, precision machining environments.

09.Machine Safy Guard System

The Coupling Threading Machine ensures safety with electrical, software, and mechanical limits on X and Z axes. Stainless-steel covers protect guideways, and a full enclosure keeps the area clean. The cabin door opens automatically via panel or M codes, while the pneumatic door coordinates with the gantry loader. All measures meet CE standards.

10.Machine Control System

The system uses SIEMENS or FANUC CNC controls for automatic, semi-automatic, and manual operations. Operators select modes and monitor machine status directly from the panel, while the touchscreen simplifies parameter input. Users can enter coupling specifications, thread types, lengths, and set cutting speed and feed rate, with real-time feedback for quick adjustments.

The intuitive touchscreen enhances programming and maintenance, improving human-machine interaction and workflow efficiency. Its design ensures fast setup, easy debugging, and smooth operation, making production more flexible and reliable.

11.Gantry Manipulator System

The gantry manipulator system integrates a flipping unit, roller conveyors, sorting module, gantry frame, and clamping fixtures for smooth handling. The flipping unit, driven by hydraulic or pneumatic cylinders, enables robotic loading and unloading, transferring couplings to conveyors for machining or discharge.

This automated process ensures continuous material flow, reduces manual labor, keeps operators away from hazardous zones, and improves overall safety and efficiency.

Discover Our Full Range