CNC Billet Cold Cutting Saw -JBS-1350

In precision machining and manufacturing, efficiency and accuracy matter most. Our JBS-1350 Series CNC billet cold cutting saw is a powerful cold cutting machine built for billet cutting, pipe cutting, log cutting, and steel bar cutting. This advanced cold saw and cold metal cutting saw meet diverse industrial cutting needs with unmatched reliability.

By integrating CNC technology with robust cutting performance, the CNC cold saw and metal cutting circular saw deliver exceptional precision for steel, aluminum, copper, and other metals. They ensure smooth, stable, and efficient operations every time.

Automated systems in CNC cold cutting machines guarantee accurate cuts, reduce material waste, and boost productivity. Programmable settings allow operators to achieve consistent results while minimizing manual effort. This improves workflow and enhances workplace safety.

Perfect for metallurgical, pipe manufacturing, aerospace, automotive, and construction industries, CNC cold saws and cold metal cutting saws are engineered for high performance. Whether producing intricate components or large-scale parts from solid billets, these cold cutting machines offer the versatility required for any project.

Composition of the Billet Cutting Machine

The Billet Cutting Saw consists of the main saw unit, hydraulic system for oil control, air cooling for blade temperature, and a centralized lubrication system for precision parts. It features a Siemens S7-1500 control system with a 10.4-inch touchscreen for advanced operation. Auxiliary equipment includes a magnetic sawdust chain, feeding trolley with measuring mechanism, and a saw blade changing device.

01 .Cut Saw Machine

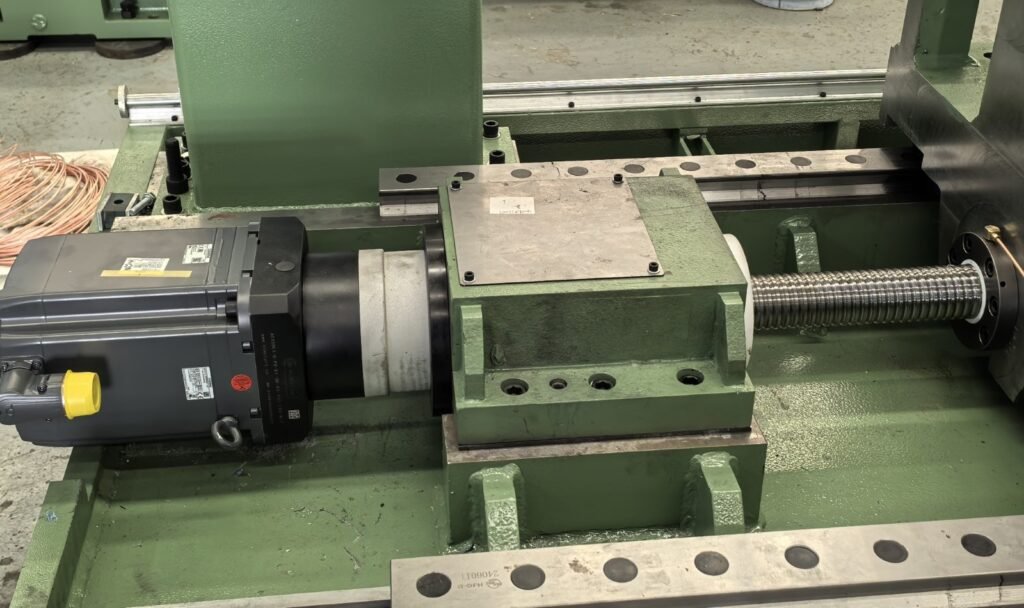

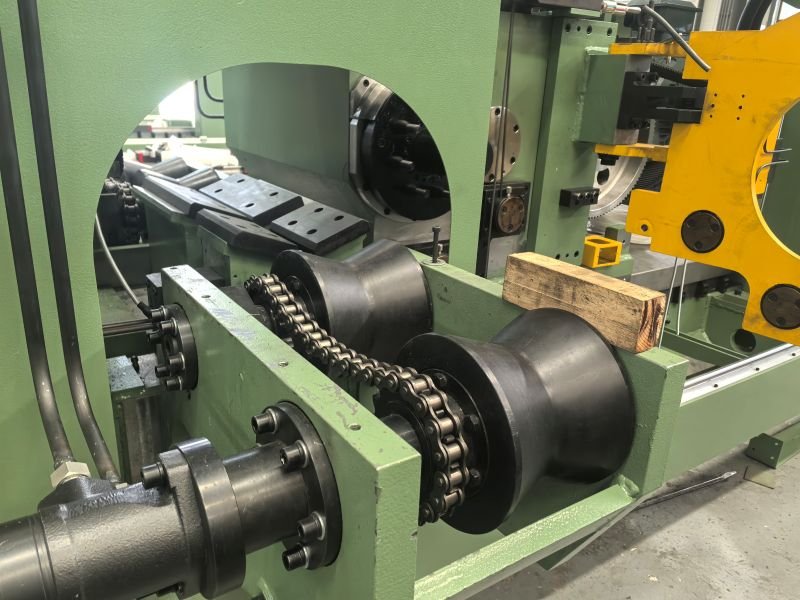

The main machine consists of the saw tool box with pulley, main transmission device, slide feed mechanism, bed base, and other essential components for precise cutting operations.

02. Hydraulic System

The hydraulic station includes a motor, hydraulic pump, heater, water cooling, oil level indicator, oil tank, and valve stand, featuring oil temperature control, level monitoring, and pressure alarm, operating from +5°C to +45°C with water cooling.

03. Air Cooling System

The air cooling system cools the saw blade and cutting area using a pipe cooler, nozzle, and pipes. It lowers tooth and disk temperature, extends blade life, and reduces equipment load for efficient operation.

04. central Lubricate

The central lubrication system provides precise, intermittent oil lubrication for guide rails, ball screws, and nut pairs. It operates at 2MPa pressure, 0.02kW power, 0.15L/min flow rate, with a 4L tank capacity.

05. Control System

The control system uses Siemens S7-1500 with integrated drive and feed servo motor. It features a 10.4-inch high-resolution touchscreen, offering advanced functionality and a user-friendly interface for efficient and precise operation.

06. Auxiliary device

Auxiliary equipment includes a magnetic sawdust chain, a measuring mechanism with feeding trolley, and a saw blade changing device equipped with a cantilever hoist and electric hoist for easy maintenance and improved productivity.

Specification Of 1350 Billet Cold Cutting Saw

| Items | Unit | Specifications |

|---|---|---|

| Performance | ||

| Processed Billet Dia Range | mm | 200 , 300, 350 ,400 |

| Max Process Billet Length | mm | 12000 |

| Max Measuring Fixed Length | mm | -5000 |

| Spindle | ||

| Spindle Rotating Pattern | continuous variable transmission | |

| Overall Ratio | 42.7 | |

| Spindle Motor Power | kw | 110 |

| Saw Blade Dia | mm | 1300 |

| Pressure Plate Flange Dia | mm | 400 |

| Feeding (X) | ||

| X Axis Travel | mm | 900 |

| X Axis Ball Screw (Dia x Lead) | mm | 63×10 |

| X Axis Servo Motor | kw | 1Fk7108 9kw |

| Fast Surface Speed | mm/min | 6000 |

| Clamping System | ||

| Drive Pattern | Hydraulic | |

| Vertical jaw travel | mm | 400 |

| Horizontal jaw travel | mm | 50 |

| Clamping Force | KN | 70-90 KN (2 sets) |

| Travel between feeding and discharging Clamp Fits | mm | 15 |

| Hydraulic System | ||

| Servo Motor Power | Kw | 22 |

| Hydraulic Pump Flow | L/min | 105 |

| Working Pressure | Bar | 120 |

| Oil Tank Capacity | L | 600 |

| Centralized Lubricating System | ||

| Size | AMO-II-150S | |

| Motor | w | 20w 220v/50HZ |

| Hydraulic Pump Flow | L/ Min | 0.15 |

| Working Pressure | Bar | 20 |

| Oil Tank Capacity | L | 4 |

| Air Cooling System | ||

| Air Flow | NM3/h | 300 |

| Working Pressure | Bar | 5-6 Bar |

| Chain Chip Conveyer System | ||

| Distance between the chip outlet and the ground | mm | 1000 |

| Conveying Speed | m/min | 2.5 |

| Motor | Kw | 0.55kw 380 v 50 Hz |

| Control System | ||

| NC System | Simens Simatic S7-1500 | |

| HMI | Touch Screen 10.4 Inch |

Mechanical Introduction of the Billet Cutting Saw

Discover Our Full Range